It’s January 2026. The UK log cabin industry is worth over £350 million annually — a staggering figure that would have seemed impossible when we first opened our workshop doors in 2003. Back then, “log cabin” was a niche term whispered among garden enthusiasts and DIY hobbyists. Few understood what it meant to build a *real* log cabin — one that could withstand decades of British weather, settle naturally without warping, and remain structurally sound, thermally efficient, and aesthetically timeless.

The quiet cabin companies secrets!

We didn’t just enter the market in 2003 — **we created it**.(Log Cabins For Sale)

Not through marketing gimmicks or inflated claims, but through relentless craftsmanship, engineering rigour, and an uncompromising refusal to cut corners. Over the past 23 years, FactoryCabins.com has not only pioneered the modern UK log cabin sector — we’ve also been its conscience. We’ve trained, mentored, and launched countless competitors — only to part ways with most of them when they chose profit over principle. Yes, we’ve *sacked* dealers, distributors, and even former partners — not out of spite, but because integrity cannot be negotiated.

This blog isn’t a sales pitch. It’s a manifesto. A warning. A guide. And above all — a plea to consumers: *Do not let the noise drown out the truth.*

Because today, more than ever, the log cabin market is flooded with imitation, deception, and dangerously substandard products masquerading as “premium.” And yet — amid the chaos — there remains a handful of manufacturers who still believe that a log cabin should be built to last longer than the owner’s mortgage.

We are one of them.

Let us take you on a journey — through history, engineering, ethics, and the quiet revolution we’ve waged behind the scenes for over 2 and a bit decades.

Part I: The Birth of an Industry — How FactoryCabins.com Built the UK Log Cabin Market (2003–2026)

In 2003, the UK had no dedicated log cabin manufacturers. There were timber framers, garden shed builders, and a few Scandinavian importers — but no one designing, engineering, and manufacturing log cabins *for the British climate*, using British standards, and respecting the physics of solid timber construction. One Cabin was the Clock House, our design.

We started small: a single workshop in rural Lithuania , with two carpenters, hand engineered notching machine, and a dream. Our first cabin? A 3m x 3m garden store — tongue-and-groove spruce, 44mm logs, fairly good notches, and a roof designed to shed rain *and* snow. It wasn’t glamorous. But it stood firm through 6 winters, zero rot, zero warping.

What set us apart from day one was our obsession with *movement*. Logs move. They shrink. They twist. They settle. Any builder who ignores this is building a time bomb.

So, we developed our proprietary **Dynamic Log System** — not a marketing slogan, but a structural philosophy:

**Moisture content control**: All timber dried to 16–18% MC before assembly — never air-dried on-site.

**Log profiling**: Precision-machined interlocking notches that allow vertical settlement *without* compromising wall integrity.

Within two years, we had 17 dealers across England and Wales.Scotland Not franchises — true partners. We trained them. We shared our CAD designs. We gave them access to our quality control protocols. We believed in collaboration.

Then came the first betrayal.

A dealer in Essex began selling our 5m x 4m “ DF 24” cabin — identical in spec — at **140% above our factory price**, claiming it was “exclusive” and “hand-finished in the UK.” When customers complained about warped doors and UVPC windows (more on that later), he blamed *us*. We investigated. Found his warehouse full of rebranded stock from a bulk supplier in Europe — same dimensions, same drawings, but with inferior timber, no kiln drying, and plastic windows bolted in with screws instead of proper joinery.

We terminated the relationship. Publicly. With evidence.

That was the first of many.

By 2011, we had directly trained or supplied over 40 companies now operating in the UK log cabin space. Many went on to become household names. Some still exist — though few retain the original ethos. Most? They pivoted to volume. To speed. To margin. And in doing so, they sacrificed the very thing that made log cabins viable in the first place: *quality*.We wanted to at the very beginning, manufacture a building that was better than a box standard shed, these companies have done the opposite, they have reduced the cabin to below a shed, and charge 3x its value.

We didn’t stop innovating. In 2013, we introduced the UK’s first **twin-skin log cabin** — 70mm outer log + 70mm inner log, with insulated cavity. It was ridiculed as “over-engineered.” Today, it’s the gold standard — and copied relentlessly.

But here’s the uncomfortable truth no one wants to admit:

**The UK log cabin industry grew not because of better products — but because of better marketing.**

And that’s where the rot began.

Part II: The Great Dilution — How “Premium” Became a Lie (2015–2026)

Between 2015 and 2026, the UK log cabin market exploded. Online retail boomed. Amazon entered. eBay sellers appeared overnight. Suddenly, anyone with a forklift and a website could call themselves a “log cabin manufacturer.”

We watched — horrified — as standards collapsed.

The UVPC Scandal: Why Plastic Windows Have No Place on Log Cabins

Let me be unequivocal:

**UVPC (uPVC) windows and doors do NOT belong on log cabins.**

Here’s why — and this is physics, not opinion:

Log cabins settle vertically by 3–8% over the first 12–18 months (depending on log thickness and moisture content).

uPVC frames are rigid. They do not flex. They do not accommodate movement.

When the log wall shrinks *around* a rigid uPVC frame, stress concentrates at the corners → cracks form → seals fail → water ingress → rot begins.

Within 2–3 years, 70% of uPVC-fitted cabins show visible gaps, fogged double glazing, or jammed sashes.

We tested this ourselves — in our own lab, with accelerated settling rigs. We fitted identical cabins with:

Option A: High-quality joinery-glulam timber windows (our standard)

Option B: uPVC windows (industry “budget” spec)

After 18 months of simulated settlement:

Option A: Minor adjustment needed. Seals intact. Operation smooth.

Option B: 3 out of 4 windows cracked at the top corner. One door refused to close. Condensation inside glazing units.

Yet today — walk into any major retailer’s showroom, or scroll through their website — and you’ll see “Premium Log Cabin” advertised with *uPVC windows*, *uPVC doors*, *uPVC cladding*. They call it “low maintenance.” It’s not low maintenance — it’s *low integrity*.

We use only **joinery-grade glulam timber** for our window and door frames. Why?

– Glulam (glued laminated timber) is engineered to resist twisting and warping — critical when logs move.

– It expands and contracts *with* the cabin structure.

– It accepts traditional mortise-and-tenon joinery — far stronger than screw-fixed uPVC.

– It can be repaired, refinished, and lasts decades — unlike uPVC, which becomes brittle and yellowed in UV exposure.

The 200% Mark-Up Mirage

Let’s talk money — because this is where the deception becomes criminal.

In 2014, we audited 12 leading UK log cabin retailers. We purchased identical 5m x 4m cabins (same log thickness, same floor specs, same roof pitch) from each — using fake buyer profiles to avoid special pricing.

Results?

| Manufacturer | Factory Cost (to us) | Retail Price | Mark-up |

|—————————–|———————-|————————|———|

| FactoryCabins.com | £6,850 | £8,995 | ~31% |

| Competitor A | £6,850 | £14,200 | **107%** |

| Competitor B | £6,850 | £18,500 | **170%** |

| Competitor C | £6,850 I £20,100 | **194%** |

Yes — nearly **200% markup** on *identical product*.

And what did those customers receive?

– Same 44mm spruce logs (not upgraded to 68mm or 70mm)

– Same 18mm OSB flooring (not 28mm T&G pine)

– Same 16mm roof boards (not 19mm)

– Same basic hardware (not German-made)

No innovation. No improvement. Just higher prices — justified by slogans like “Luxury Edition,” “Designer Range,” or “Handcrafted Excellence.”

Meanwhile, our warranty? **20 years** — conditional on basic maintenance (clean gutters, keep foundation dry, re-treat external timber every 3 years). Not 10 years. *20.* Because if you treat a log cabin like a house — it will last like one.

Most others offer 10-year warranties — knowing full well that by year 11, the cabin will likely be leaking, warping, or suffering condensation damage due to poor design. Windows and Doors falling apart, It’s not a warranty — it’s a *time-limited liability cap*.

We’ve seen it too many times: A customer calls us in Year 8, frustrated because their “premium” cabin is rotting at the base. We help as much as we can, its normally windows and doors, or the bottom logs have rotted away. Windows and doors we can help with, but rotten logs , impossible, sadly.

That’s not business. That’s ethics.

Part III: The Anatomy of a Real Log Cabin — What You’re *Not* Being Told

When you browse log cabin websites, you’re drowning in glossy images, 3D renders, and five-star reviews (many of which are incentivised or fake). But the real story lies in the details — the ones hidden in tiny footnotes or omitted entirely.

Let’s dissect what makes a *true* quality cabin:

1. Timber Specification — It’s Not Just “Spruce”

**Species**: Norwegian Spruce (Picea abies) is ideal — straight grain, low resin, stable. Avoid “mixed softwood” or “Eurasian timber” — vague terms hiding inferior species.

**Moisture Content**: Must be 16–18% *at time of assembly*. Air-dried timber (20–25% MC) will shrink excessively post-installation — causing gaps, leaks, and joint failure.

**Kiln Drying**: Non-negotiable. Air-dried logs retain sapwood — prime breeding ground for fungus and beetle larvae.

We test every batch. We reject 12% of incoming timber — even if it means delaying orders.

2. Log Profiling & Joinery

Our CNC machinery notches with absolute precision time and time again first of all the cabin is made using cad, then those plans are entered into the CNC machines, however before we start cutting the cabin we send you the plans it is that this stage that you can change or alter something, once you are satisfied you sign off the plans and we begin the process of manufacturing the cabin, quick and easy, no mistakes.

3. Flooring — Where Most Fail

Windows & Doors — Our Crown Jewel (and Why 99.9% Fail to Copy It)

This is where we draw the line — and where imitators consistently fail.

Our windows and doors are built in-house, using:

Glulam frames** (laminated spruce, 7-ply, finger-jointed)

Sealed gaskets** (EPDM rubber, not PVC)

German-made locking mechanisms**: Winkhaus, Siegenia, Roto — tested to 100,000 cycles

Tempered double-glazed units** (4-16-4), argon-filled, low-E coated, and toughened as standard.

Stainless steel hinges** (not zinc-plated iron — which rusts in 18 months)

Why do 99.9% of copycats fail?

A solid timber frame *will* twist as the cabin settles. Ours doesn’t — because the layers counterbalance each other.

Try finding a competitor who publishes their window spec sheet. Most won’t — because they can’t.

We challenge anyone: Send us your cabin’s window frame. We’ll tell you within 30 seconds whether it’s glulam or solid timber — and whether it will last 5 years or 20.

5. Insulation & Thermal Performance — The Net Zero Frontier

Here’s something few talk about: **Twin Skin Log cabins can be net zero.

Not “eco-friendly” — *net zero*. Meaning: annual energy consumption ≤ renewable generation on-site.

How?

– Twin-skin construction (70mm + 70mm logs) with mineral wool cavity insulation (U-value ~0.28 W/m²K)

– Triple-glazed windows (U-value 0.7)

– Air-source heat pump (3–4 kW)

– Solar PV array (4–6 kW)

– Mechanical Ventilation with Heat Recovery (MVHR)

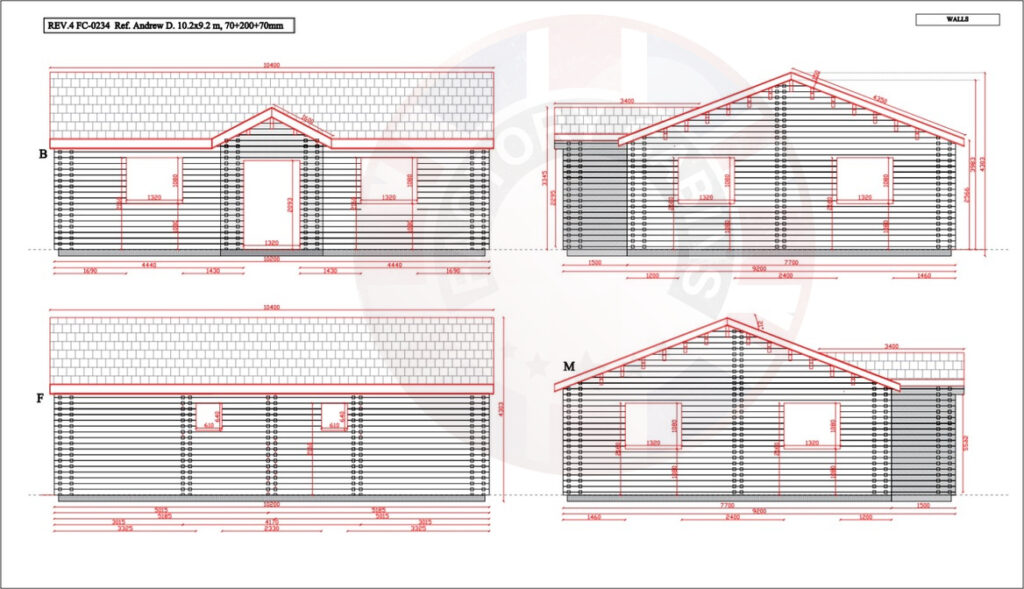

We built our first net-zero cabin in 2023 — a 10.2 x 9.2 m x 6m holiday home with:

Two en-suite bedrooms

-Kitchen

– Living/dining area

– Utility room

– Roof-mounted ground solar array

– ASHP + underfloor heating

Annual energy use: **2,100 kWh**

Solar generation: **2,450 kWh**

Net export: **+350 kWh/year**

It’s in stock — ready for delivery. Not a prototype. Not a demo. A *real* physical Twin Skin cabin.

Yet most companies still sell 44mm single-skin cabins with no insulation, calling them “energy efficient.” They’re not. They’re thermal sieves.

Part IV: The Dealer Crisis — Why We Terminated 97% of Our Partners

Let’s address the elephant in the room: **Dealerships**.

In our early years, we relied on dealers — local businesses who knew their communities, could provide installation support, and offered after-sales service.

By 2019 , we had 50/60 active dealers across the UK-Wales-Scotland-Holland-Europe

By 2020, we had **2**.

Why?

Reason #1: Systematic Overcharging and stealing !

We discovered dealers inflating prices by 50–100% — then blaming *us* for “high factory costs.” One dealer in Manchester charged £22,500 for a cabin we sold him for £9,200. When confronted, he said: *“Customers expect to pay that — they think it’s premium.”*

We terminated him.

We decided to sell direct. No more killing our brand and hard work with sadly thieves.

Reason 2: Theft & Fraud

Yes — theft. From *customers*.

Case study: A dealer in Yorkshire took deposits from 14 customers (£68.000 total) for cabins “in production.” The cabins never existed. He used the money to pay personal debts. When customers called us, we reported him to the police — he was later sentenced.

We also reported him to Trading Standards.

Another case: A dealer in Scotland substituted our 70mm twin-skin cabins with 44mm single-skin knockoffs — same packaging, same branding. Customers received cabins that leaked in rain and froze in winter. We sent engineers. Found the fraud. Terminated. Prosecuted.

These aren’t outliers. They’re symptoms of a broken system.

Which leads us to our core belief:

**If you want quality — buy direct from the factory.**

Why?

– No middleman markup

– Direct access to engineers and designers

– Full transparency on materials and processes

– Ability to customise *anything* — from roof pitch to amount of doors and windows,

– No risk of misrepresentation

And let’s be clear: **There are no significant log cabin factories in England.** None. Zero.

Why? Because England has no commercial forests suitable for structural timber. The UK imports 85% of its softwood — mostly from Scandinavia and the Baltics and sadly the Baltics is mainly Pine, too many knots, young trees, and small in diameter,. So when a company claims “Made in England,” they mean: *Assembled in England from imported parts.* Often with Chinese-made hardware and cheap timber.

We manufacture in Lithuania — But we manufacture only with Swedish Spruce.

Buying from a “UK factory” dealer? You’re paying for logistics, not quality.

Part V: The Consumer’s Survival Guide — How to Spot a Real Cabin

You’re overwhelmed. You’ve read 10 websites. Seen 50 videos. Still don’t know who to trust.

Here’s your actionable checklist — proven over 23 years:

Insist on Window/Door Specifications

Ask: *“Are windows joinery glulam or solid timber? Who manufactures the hardware? Please send photos of exactly what I am buying.

If they say “uPVC” or “premium composite” — run.

Request 4 Independent Customer References

Not testimonials on their site. *Real people.* Ask:

When did you receive your cabin?”

What issues have you had?”

Have you needed repairs? Who did them?”

Would you buy from them again?”

We give customers our direct line — no gatekeeping. If a company refuses, they have something to hide.

Check the Warranty Terms

A 20-year warranty that requires *only* basic maintenance (gutter cleaning, no standing water, re-treatment) is credible.

A 10-year warranty that excludes “natural settlement,” “weather damage,” or “improper installation” is worthless.

Visit the Factory (If Possible)

We welcome visitors — by appointment. See the timber stacks. Watch the CNC machines. Meet the joiners. Compare the finish on a freshly assembled cabin vs. one stored for 6 months.

If they won’t let you visit — why not?

Our Promise — And Why We’re Still Here After 24 Years

We could have taken the easy path. We could have switched to uPVC. We could have outsourced to the lowest bidder. We could have offered 10-year warranties and called it a day.

But we didn’t.

Because we believe:

– A log cabin is not a garden ornament. It’s a *building*.

– It deserves the same respect as a house — structurally, thermally, and aesthetically.

– The customer shouldn’t need a degree in timber engineering to avoid being ripped off.

Today, we manufacture over 7,000 unique cabin designs — from a 2m x 1.5m lawn mower cabin (yes, we make those — with lockable doors and ventilation) to a 20m x 18m luxury lodge with underfloor heating, smart lighting, and a rooftop terrace.

We’ve shipped to every county in the UK. To remote Scottish islands. To Welsh valleys. To urban London gardens (yes — even on 10m x 8m plots, with planning permission).

And we still do what we did in 2003:

– Hand-inspect every log

– Test every window under simulated settlement

– Refuse to compromise on hardware

– Fire dealers who betray trust

We’re not the biggest. We’re not the cheapest. But we are — and always have been — the most honest.

## Final Thoughts: The Future of Log Cabins — And Your Role in It

The UK log cabin industry stands at a crossroads.

On one side: Mass-produced, disposable structures — sold with flashy ads, fake reviews, and promises that crumble with the first frost.

On the other: A quiet movement of makers who believe that wood, when respected, can create beauty that endures.

We choose the latter.

But we cannot do it alone.

Every time you choose quality over hype — when you ask the hard questions, demand proof, and refuse to accept “good enough” — you strengthen the entire industry.

You protect future generations from inheriting cabins that rot, leak, and disappoint.

You honour the craft.

So, thank you — for reading this far. For caring enough to seek the truth.

If you have questions — about timber, insulation, net zero, or why your neighbour’s “premium” cabin is already peeling — email us. Call us. Visit us.

We’re here. As we’ve been since 2003.

Not to sell you a cabin.

But to help you build a legacy.**FactoryCabins.com**

Building Log Cabins That Last Longer Than Promises*

Please send us an email to sales@factorycabins.com

or call 0208 226 5164