Now, let’s delve into the compelling reasons why it is fundamentally flawed to equate superior timber-frame net-zero buildings with their garden-variety counterparts. These distinctions encompass variations in construction techniques, materials, functionality, and overall value.

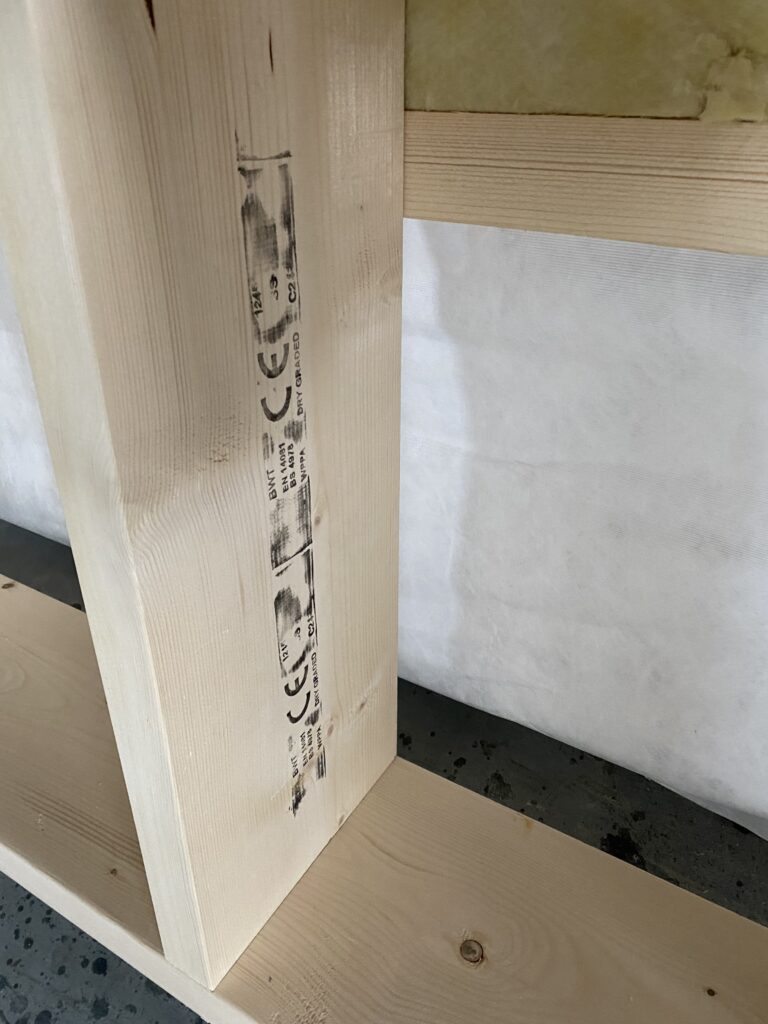

First and foremost, the materials employed in crafting superior timber frame net-zero buildings stand in stark contrast to those found in their garden-variety counterparts. Net-zero structures often utilize high-quality, sustainable materials. An exemplary instance is the meticulously selected and graded C24 wood, renowned for its durability and longevity. In contrast, garden-variety structures typically resort to unseasoned, low-quality wood bereft of any grading. The divergence in materials alone can significantly impact the quality and longevity of the final construction.

Moreover, the construction processes employed in crafting net-zero buildings far surpass the rudimentary techniques used in garden-variety structures. Advanced framing techniques are used in net-zero structures to prevent thermal bridging and improve insulation. This results in a structure that is very energy efficient. Conversely, garden-variety buildings resort to rudimentary framing techniques, resulting in insufficient insulation and a less efficient structure.

In terms of performance, net-zero buildings outshine their garden-variety counterparts. A meticulous focus on energy efficiency guides the creation of net-zero buildings, equipping them with features such as triple-glazed windows, superior insulation, and airtight construction. These features substantially reduce energy consumption and greenhouse gas emissions. On the contrary, garden-variety structures often compromise on insulation and persist with outdated, inefficient heating and cooling systems, leading to increased energy costs and a heightened environmental impact.

Total value is yet another critical factor that distinguishes superior net-zero timber frame buildings from their inferior garden-variety peers. While a net-zero timber frame building may entail a higher initial cost, its long-term value eclipses that of its less advanced counterpart. Thanks to their superior construction, durability, and energy efficiency, net-zero buildings boast a significantly lower long-term cost of ownership. Conversely, garden-variety structures may appear cheaper initially but often accrue higher long-term costs due to increased energy consumption and maintenance requirements.

To liken a high-quality timber-framed net-zero building to a garden-variety structure is akin to comparing a sleek, well-maintained car with a dilapidated, old vehicle. While they may share certain materials like rubber, glass, and metal, the disparities in total value, performance, and quality are unmistakable. Expecting a subpar building constructed with inferior materials and construction standards to rival its superior counterpart is simply unjust.

Furthermore, the very act of making this comparison is flawed, assuming the erroneous premise that all timber frame buildings are created equal. Just as there exists a spectrum of car performance and quality, the same holds true for timber frame houses. Not only is it erroneous to lump all timber frame buildings together, but it also disregards the progress and innovations occurring in the construction industry.

It is both misguided and misleading to equate superior timber-framed net-zero buildings with their garden-variety, poorly insulated counterparts. Material disparities, construction techniques, overall value, and performance stand as clear differentiators. By noticing these differences, we can really understand why premium timber-framed net-zero buildings are so valuable and of such high quality, as well as how important they are for promoting sustainability.

Our unwavering commitment lies in exploring the pivotal role that timber plays in achieving net-zero emissions by 2030 as we endeavour to create a sustainable and environmentally conscious future. Often underappreciated, timber holds significant ecological and economic benefits. In this comprehensive piece, we delve into its significance, its multitude of applications, and its potential to revolutionise various industries.

The Environmental Impact of Timber

Timber emerges as a potent ally in the battle against climate change, primarily due to its status as a renewable resource that sequesters carbon. In stark contrast to fossil fuels, the utilisation and production of timber contribute to reduced atmospheric carbon dioxide emissions, manifesting in the following ways:

- Carbon Sequestration: Timber acts as a carbon sink, absorbing and storing carbon dioxide as it grows. Trees represent a natural means of curbing greenhouse gas emissions, with the potential to store up to 1,000 kg of carbon per cubic metre.

- Ecological Stewardship: Responsible forestry practices, which involve selective harvesting of mature trees, maintain a favorable carbon balance in forests. Furthermore, sustainable forestry safeguards invaluable habitats and fosters biodiversity.

- Energy Efficiency: Timber’s lightweight, insulating properties, and adaptability result in reduced energy consumption in buildings. Wood-framed structures exhibit a smaller carbon footprint and lower energy costs.

Harnessing Timber in Construction

The construction industry stands as one of the primary contributors to carbon emissions. However, we can significantly reduce its environmental impact by incorporating timber into construction projects, with the following benefits:

- Eco-Friendly Building Materials: Timber provides a sustainable alternative to conventional construction materials like steel and concrete. Engineered wood materials such as cross-laminated timber (CLT) are enabling the construction of tall buildings with reduced carbon footprints.

- Speedy Construction: Prefabrication of timber components facilitates faster and more cost-effective building completion, minimizing disruptions to neighboring communities.

- Urban Planning: Wood’s versatility has inspired innovative architectural concepts, including timber skyscrapers, offering visually appealing and environmentally responsible solutions for urban expansion.

Timber’s Role in Industry

Timber’s influence extends beyond construction, particularly in industries with high emissions. It has made diverse and substantial contributions, including:

- Automotive Sector: Manufacturers are increasingly turning to wood-based composites for vehicle interiors to reduce weight and lower environmental impact.

- Furniture and Timber Products: The production of furniture and wood products is transitioning towards eco-friendly and sustainable practices, employing certified sustainable timber.

- Shipping and Packaging: The use of timber pallets and containers, known for affordability, strength, and environmental friendliness, diminishes the carbon footprint of the shipping and packaging sector.

Timber as a Carbon Offset

Timber holds the potential to serve as a significant tool for mitigating carbon emissions. Planting trees and preserving forests become critical strategies for individuals and businesses seeking to reduce their carbon footprint:

- Soil Restoration: Investment in sustainable forestry projects and reforestation initiatives can help individuals and businesses become more carbon-neutral, balancing out carbon emissions.

- Carbon Emissions Offsetting: Carbon-sequestering timber projects can generate valuable carbon credits, enabling businesses to invest in sustainable practices and offset their emissions.

Beyond its role as a building material, timber emerges as a pivotal asset in our quest to achieve net-zero emissions by 2030. Its impact on the environment, adaptability in construction, versatility across various industries, and potential for carbon offsetting make it a formidable force for positive change.

Please call us for more inormtion.

+44 208 133 5164