Beyond Standards, Beyond Depreciation: Creating Legacy Retirement Homes That Challenge Convention

The aspiration for a peaceful, safe, and valuable retirement home is universal. But the reality delivered by much of the market, and especially the park home industry regulated by standards such as BS 3632:2023, is too often a tale of compromise, early depreciation, and energy inefficiency masquerading as compliance.

We don’t simply construct timber frame houses; we create legacies. We shatter the limits of the standard, providing bespoke, net-zero ready havens crafted not to lose value, but to gain – and to give you unbeatable comfort, sustainability, and a huge return on your investment. Let’s explore why our spec isn’t simply superior; it’s a root-and-branch reimagining of what a retirement home should be.

Obliterating BS 3632:2023: A Standard Built on Compromise

BS 3632:2023 establishes a standard, but it’s a standard based on manufacturing constraints and cost-saving, rather than actual performance or durability. Its very nature tends to require compromises that directly affect your quality of life and your asset’s value:

1. The Ventilation Paradox: The most obvious shortcoming is the need for ventilation holes in all walls. This is not some sophisticated energy-conserving methodology; it is a crude admission of defeat. It makes up for a lack of inherent airtightness and moisture control in conventional construction. These openings are actual energy leaks, making your heating system do extra work and negating any pretension to genuine efficiency. Our solution? We construct inherently tight buildings from the foundation.

2. The Depreciation Disaster: The dirty secret of much of the BS 3632 market is catastrophic depreciation. It’s not uncommon for standard park homes to lose 90% of their value over 10 years. This isn’t wear and tear; its systemic devaluation driven by perceived lower quality, inherent limitations, and the sheer volume of similar, depreciating units. Buying one is often akin to setting fire to a significant portion of your capital.

3. Performance Shortfalls: Although BS 3632 requires some U-values (a measure of heat loss), they are frequently only the minimum that can be attained using conventional techniques and materials. Genuine thermal efficiency and year-round comfort demand much more substantial solutions.

Our Timber Frame Specification: Engineering Excellence for Legacy

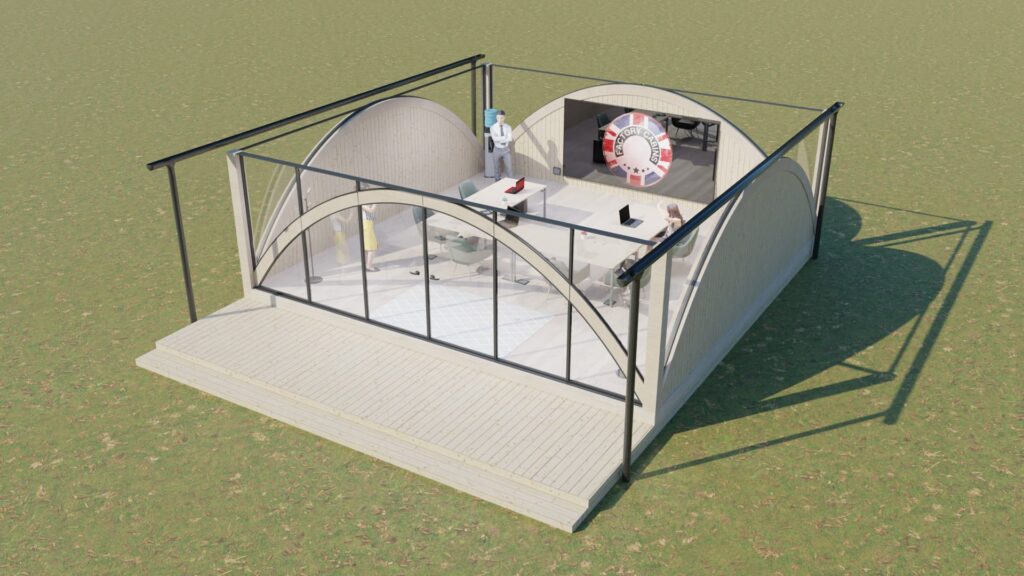

Our properties are designed to an entirely different specification, with the finest materials and precision building methods. Disregard “park home” constraints; consider bespoke, high-performance architectural home. Let’s break down the excellence intrinsic in our specification (as represented in the Stephen Reilly design):

Unmatched Thermal Envelope (U-Values that Impress):

Walls: Consider the depth: 250mm of Knauf Expert insulation in the principal studwork, with an extra 50mm layer on the outside, divided by a service cavity.

This provides an unbroken thermal barrier, cutting thermal bridging by a huge amount. Added to the natural accuracy of timber frame building and state-of-the-art air barriers (Tyvek Soft, carefully taped SIGA joints), our wall U-values don’t merely reach standards; they shatter them, hitting figures nearing Passivhaus principles.

That equates to little heat loss and heating bills slashed dramatically.

Roof: 300mm of Knauf Expert insulation within the rafter area, with an additional 50mm layer beneath the service cavity. Combined with Tyvek PRO+ tape for final airtightness and a highly ventilated roof structure, warmth just doesn’t get away upwards.

This is thermal performance leagues above conventional trussed roofs with less insulation.

Floor: 200mm of Knauf Expert insulation under a strong moisture-resistant chipboard deck, resting on accurately engineered timber sections. Cold feet are excluded and heat loss into the ground is prevented.

Airtightness: The Silent Champion of Efficiency: Never mind required holes! Our preoccupation is closing the envelope. SIGA tapes and membranes are the gold standard, carefully detailed at every connection point, penetration, and junction.

Coupled with the precision-fit of components that comes naturally with our off-site manufacturing process, we routinely achieve air-tightness levels that make forced ventilation holes a thing of the past. This is the cornerstone of real energy efficiency and comfort, banishing drafts and providing even temperatures.

Moisture Management Done Right:

A crucial but easily neglected factor. Our spec includes several layers of defence:

External: Termo wood cladding (Class A durability) on a 20x45mm battened cavity (Tyvek Soft breather membrane behind) so that driving rain is shed and any moisture that enters the cladding may drain and evaporate.

Internal: The wind barrier of impregnated plasterboard provides a further layer of protection within the wall construction. The PE film in the wall and roof is a vapour control layer (VCL), positioned to ensure that warm, moist internal air cannot condense into the structure.

The multi-layer concept ensures a dry, healthy, and long-lasting building fabric.

Robustness & Longevity:

Structure: Carefully designed timber sections (45x245mm walls, 45×220+95mm rafters) on close centres (600mm) form an extremely robust and stable framework. Stainless steel A2 fixings throughout provide resistance to corrosion.

Protection: Rodent bands at the base keep pests out. Completely prepared window/door openings with metal sill plates stop rot. Top-quality, long-lasting exterior claddings (such as Termo wood) provide decades of low-maintenance service.

Materials: We specify premium materials throughout – Knauf insulation, Tyvek membranes, SIGA sealing, impregnated boards, moisture-proof chipboard, and galvanised fixings for structural connections. This isn’t just about meeting a spec; it’s about exceeding lifespan expectations.

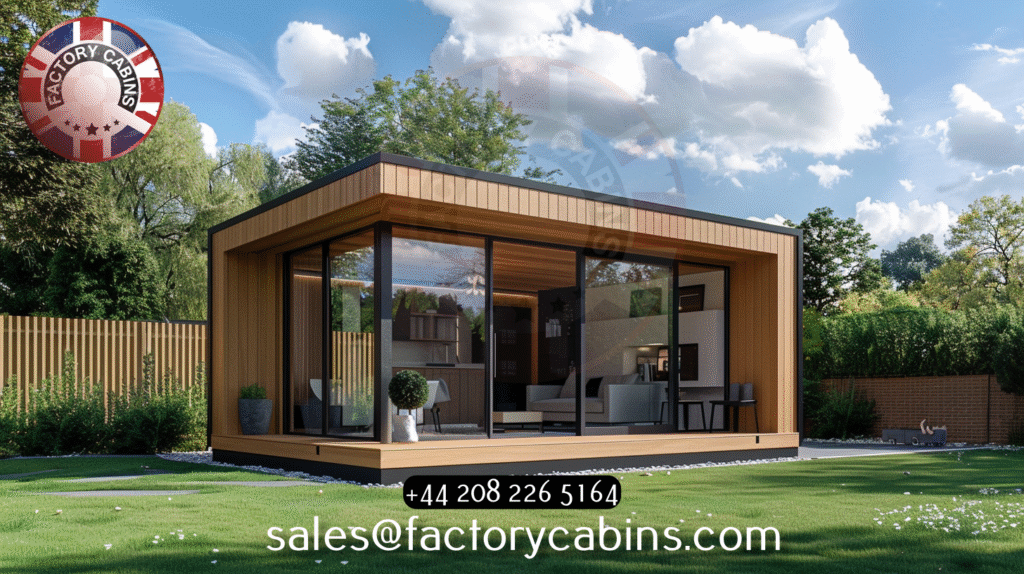

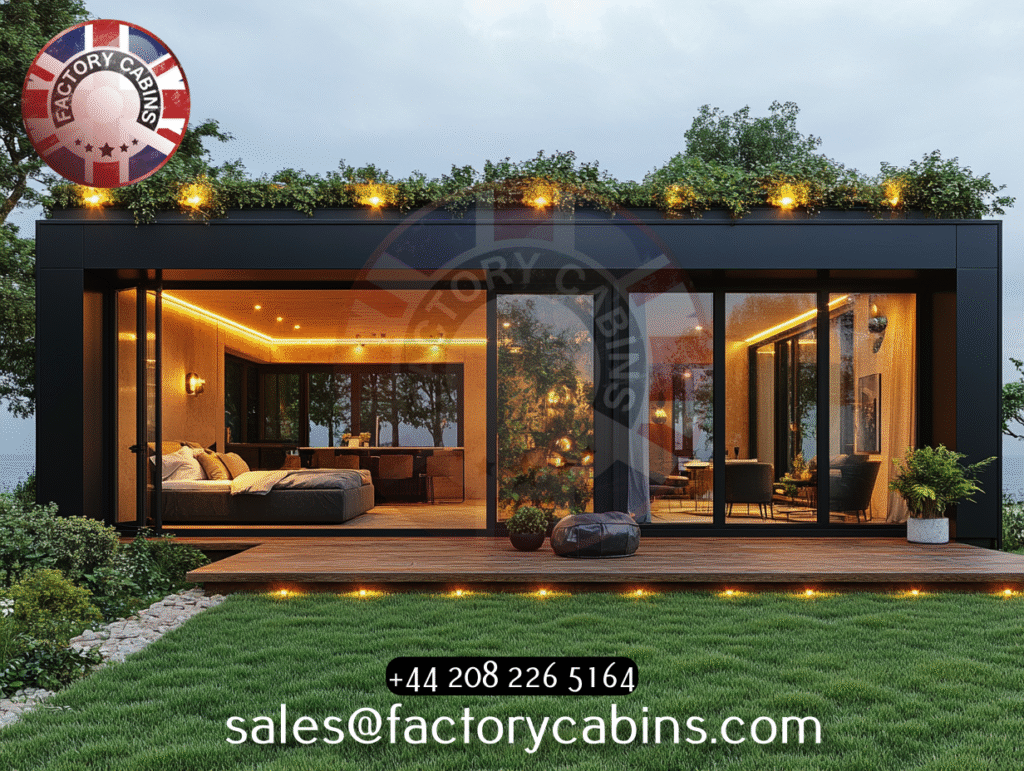

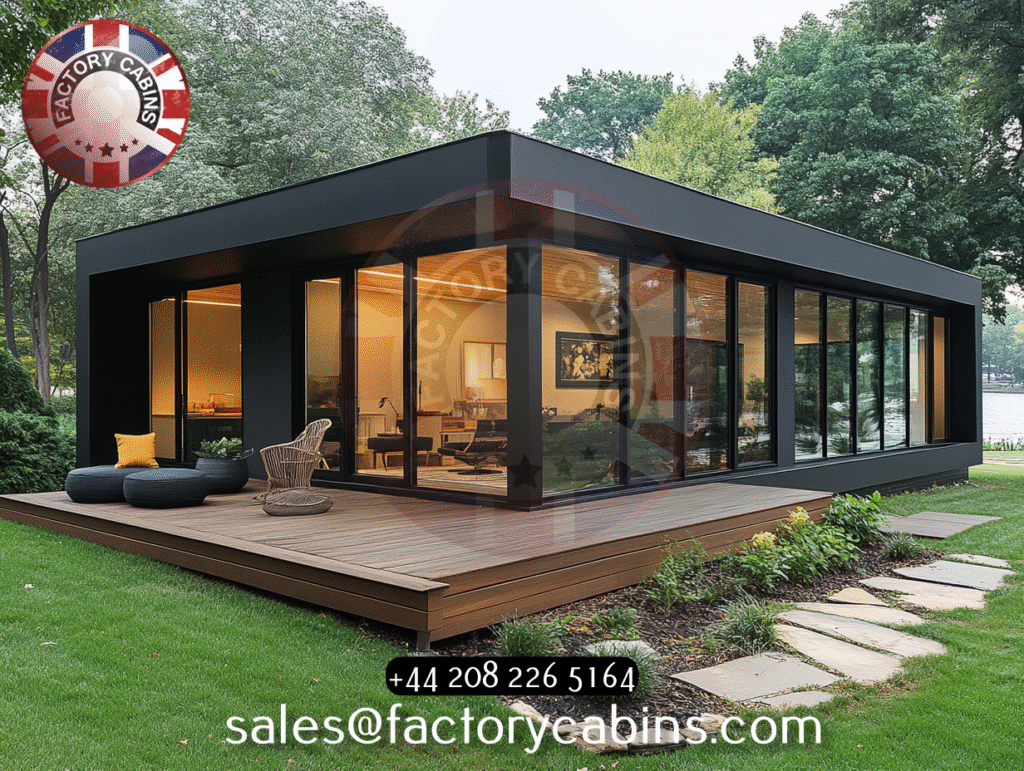

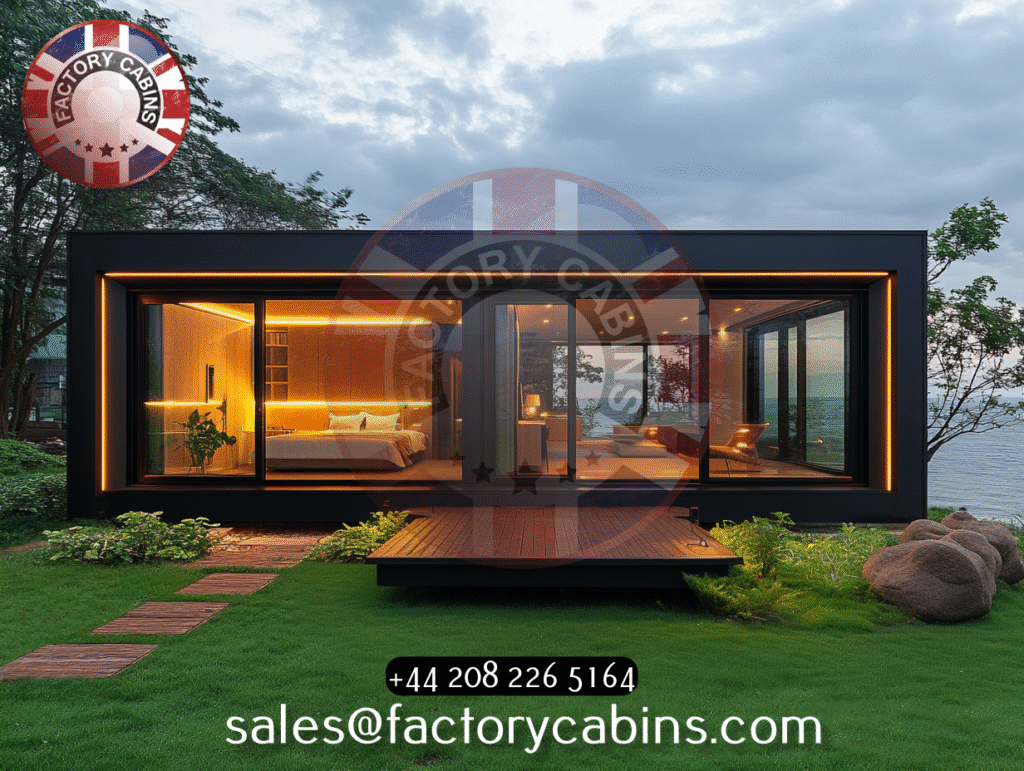

Bespoke Design & Aesthetic Freedom: Your home in retirement must reflect your personality, not a catalogue option. Our timber frame system provides unparalleled flexibility.

Any Layout: Internal walls (such as the 45x95mm framed partitions with 100mm insulation) are non-loadbearing, so you can arrange the internal space precisely how you want as now or at any time in the future.

Cladding Option: Termo wood is only one possibility. Consider brick slips, render, composite panels, or any other high-quality finish – you decide to make your home truly individual and visually striking, complementing its environment.

Doors & Windows: Standard are triple-glazed, A-rated PVC windows and doors (sliding or entrance) with superior thermal performance, security, and acoustic insulation. Standard is white, but custom finishes are available. These are not merely holes in the wall, but rather high-performance elements carefully integrated into our tight envelope.

Net Zero Ready: It’s the Fabric, First and Foremost:

Real net zero does not come from slapping a low-performing box with solar panels. It begins with an ultra-high-performance building fabric that reduces energy demand to the bone – resulting in a large energy deficit relative to anything constructed to standard BS 3632:2023 or even average new builds.

Our exceptional U-values and industry-leading air-tightness mean the energy required to heat your home is minimal.

This low inherent demand means that when you do add renewable energy sources (like solar PV or heat pumps), they become incredibly effective, potentially covering all your energy needs and truly achieving net zero. We build the essential foundation for net zero living.

Appreciation, Not Depreciation: The Ultimate Return on Investment

This is where the paradigm really changes. Traditional Park homes are frequently financial black holes. Our bespoke, engineered timber frame homes on freehold land are assets that will retain and appreciate: This should be your goal!

1. Freehold Land: Owning the land your home is on is a cornerstone of long-term value. It gives you security and permanence that’s missing from leasehold park models.

2. Unmatched Quality & Durability: The synthesis of high-quality materials, painstaking engineering, and strong construction methods leads to a home constructed to endure generations, not decades. This intrinsic quality is acknowledged in the marketplace.

3. Future-Proof Compliance (BS 3236 & beyond): Though we surpass today’s BS 3632, the future heralds more stringent standards such as those enshrined in newer frameworks (BS 3236 is a pointer in this direction). Our houses are planned in expectation of these elevated requirements, especially in the areas of energy efficiency (U-values, airtightness) and sustainability. When these become mandatory, homes already constructed to our specification will be in great demand and command a sizeable premium. We’re creating tomorrow’s resale value today.

4. Bespoke Desirability: An individual, high-quality, architecturally designed house on its own plot is by nature more desirable and valuable than a mass-market unit on a densely populated estate. Your house is unique.

5. Energy Efficiency as Value: Skyrocketing energy prices render the extremely low operational costs of our dwellings a tremendous financial benefit, which directly equates to greater market value. Purchasers pay a premium for surety and reduced overhead.

Why Choose Us? Defining Market Leadership

We are not another builder, but innovators taking on a complacent marketplace:

Technical Leadership: Our specs (such as the Stephen Reilly example) are open and reflect a commitment to physics-based building science, rather than merely complying with minimum codes. We invest in the layers (insulation, airtightness, moisture management) that provide real-world performance.

Design Vision: Retirement homes don’t have to be dull boxes, but rather wonderful, inspiring places. Our tailored solution releases architectural possibility unavailable with off-the-shelf systems.

Ethical Construction: The 90% depreciation typical in the regular market is, quite simply, not acceptable. We construct houses that are a true investment in your future and a heritage for your household. We view net zero as a requirement attained by essential building brilliance, not greenwashing with bolt-on technology.

Champions of Change: We call for a root and branch move away from standards that entrench poor performance (such as compulsory ventilation holes) and towards standards that encourage high-quality, durable, and efficient homes (such as the path BS 3236 points towards). The government’s net zero aspirations will be empty without tackling the underlying performance of the housing stock.

Your Retirement Legacy Begins Here The construction of your retirement home ought to be a positive experience in pursuit of comfort, security, and enduring value. Do not accept the depreciating concessions of the conventional market regulated by BS 3632:2023.

Welcome the future of retirement living. Choose a home engineered to obliterate outdated standards. Choose a home wrapped in layers of premium insulation and sealed to perfection. Choose a home bathed in natural light through triple-glazed windows, uniquely designed to your vision. Choose a home built on freehold land, constructed with materials and methods that ensure it stands the test of time.

Choose a home that delivers a massive return on investment through minimal running costs and inherent appreciation potential. Select a Net Zero Ready legacy, not a depreciating liability.

We don’t merely construct homes; we create custom, high-performance sanctuaries intended to be your forever home and a worthwhile asset for generations. Let us construct your outstanding retirement legacy, together. Discover the difference that real specification leadership makes.