Beyond Compromise: How Twin-Skin Engineering Defines the Log Cabin Ranges Across All Sizes

https://factorycabins.com/product-category/the-ev-log-cabin-range

Here we have a very detailed listing, of why a Twin Skin Log Cabin, is truly the best choice.

This report provides a deep research analysis of Factory Cabins’ EV Log Cabin range, focusing on how its proprietary twin-skin interlocking technology creates a distinct competitive advantage over conventional single-skin log cabins available in the UK market.

The analysis evaluates the technological underpinnings of this system across three core pillars: thermal performance, which enables year-round usability; structural integrity, derived from material science and precision manufacturing; and practical versatility, which unlocks the full potential of garden space. By examining these attributes across the entire EV product line, from compact single-story models to expansive multi-story configurations, this report demonstrates that the twin-skin system delivers consistent, quantifiable benefits regardless of cabin size or intended use. Furthermore, it contextualizes these technical advantages within the company’s strategic positioning as the Lithuanian originator of these designs, offering a transparent, direct-from-source purchasing model that challenges prevalent industry norms.

Thermal Performance: Engineering Year-Round Comfort

The primary differentiator of Factory Cabins’ twin-skin EV Log Cabin range is its engineered approach to thermal performance, which fundamentally addresses the limitations of traditional single-skin constructions and establishes a new standard for year-round usability in the UK’s temperate maritime climate. Unlike conventional cabins that rely on the inherent insulating properties of solid timber, the twin-skin system integrates high-performance insulation directly into the wall structure, creating a robust thermal envelope that minimizes heat loss and prevents condensation.

This architectural innovation is not an afterthought but a core design principle, ensuring consistent comfort whether the cabin is used as a winter office in Sussex or a coastal retreat in Kent. The system’s efficacy is rooted in its layered construction, which separates the structural elements from the insulating function, allowing each component to perform its role optimally. For instance, the principles of timber engineering emphasize the importance of loadbearing structures and distinct component layers, a philosophy central to the twin-skin design.

The physics of heat transfer in a typical single-skin log cabin, even at a substantial 70mm thickness, proves insufficient for maintaining comfortable indoor temperatures throughout the British year.

Timber possesses a limited thermal resistance, often referred to as its R-value, which is approximately 1.25 per inch .As outdoor temperatures drop, particularly below 5°C, this level of insulation allows heat to escape rapidly through the walls, leading to cold interior surfaces. These cold surfaces cause warm, moist air from inside the cabin to cool to its dew point, resulting in condensation forming on windows, walls, and corners. This persistent dampness can foster mould growth, compromise timber integrity, and render the cabin unusable for several months annually. While some suppliers may advertise their single-skin cabins as “insulated,” this often involves adding foil-backed insulation boards to the interior or exterior of the timber frame, a superficial measure that fails to address thermal bridging at joints and does little to prevent interstitial condensation within the timber itself. In contrast, Factory Cabins’ twin-skin system constructs the insulation into the very fabric of the wall.

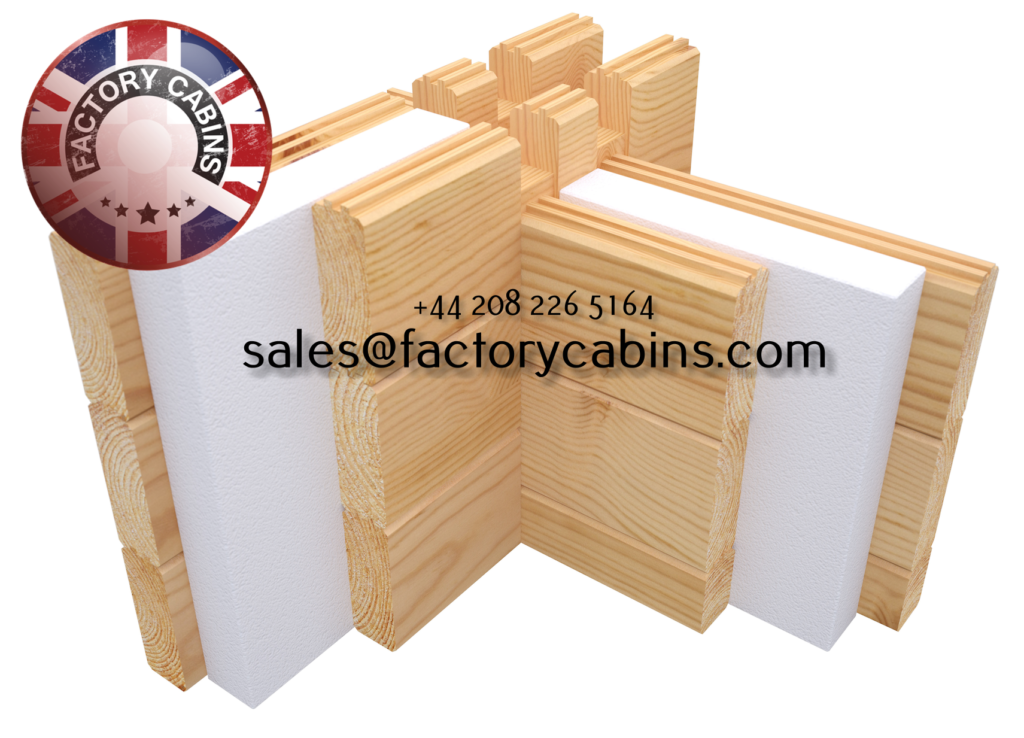

The twin-skin construction consists of two independent skins of premium Scandinavian spruce timber, separated by a precisely engineered cavity. This cavity is filled with high-grade insulation material, creating a continuous thermal break that single-skin designs cannot replicate. This method achieves significantly lower U-values, a standard metric for measuring the rate of heat transfer through a building element. Factory Cabins reports U-values as low as 0.18 W/m²K for its twin-skin cabins, a figure dramatically superior to the 1.2–1.5 W/m²K typical of uninsulated or poorly insulated single-skin alternatives. To put this into perspective, these U-values meet and exceed the standards set for modern residential construction, where the required U-value for walls is typically around 0.30 W/m²K according to NHBC Standards 2024.

This level of performance means that the cabins maintain stable internal temperatures with minimal heating input, often requiring only a small 1.5kW panel heater to remain comfortable even during the coldest Sussex winters. This capability is a direct result of rigorous engineering, developed in response to harsher continental climates in Factory Cabins’ native Lithuania, ensuring resilience against unexpected cold snaps common even in the UK.

A crucial, yet often overlooked, benefit of this integrated thermal system is its inherent moisture management capability. The insulated cavity acts as a buffer zone, preventing the warm, humid air generated indoors from coming into direct contact with the cold outer skin of the cabin

This effectively eliminates surface condensation, preserving both the timber structure and the indoor air quality. The design further incorporates vapour barriers to prevent moisture from penetrating the insulation and causing interstitial condensation—the silent degradation of timber integrity caused by moisture accumulation within the wood itself. This comprehensive approach to moisture control is vital for the long-term durability of any timber building, especially in regions with high humidity like the coast of Kent. The principle of managing moisture and ensuring dimensional stability is a key focus in modern timber construction, and the twin-skin system embodies these best practices from the ground up.

This thermal advantage is not contingent on the size or complexity of the cabin but is instead a fundamental property of the twin-skin wall construction itself. Whether examining a compact single-storey EV20 designed as a garden office or a large, multi-storey EV50 configured as a holiday let, the thermal envelope is defined by the same precise engineering.

The interlocking corner joinery ensures that the integrity of this thermal barrier is maintained at every junction, preventing drafts and thermal bridging—a common weak point in conventionally built structures.

The larger the footprint of a cabin like the EV40 or EV50, the more significant the cumulative benefit of a consistent, high-performance thermal envelope becomes, as overall heat loss is directly proportional to the surface area exposed to the external environment.

Thus, the twin-skin system provides a scalable solution that guarantees superior thermal performance across the entire EV range, enabling genuine year-round utility irrespective of the building’s dimensions or configuration.

Structural Integrity: The Synergy of Precision and Material Science

| Feature | Conventional Single-Skin Cabin | Factory Cabins Twin-Skin Cabin |

| Wall Construction | Solid timber logs (e.g., 44mm or 70mm thick) susproc.jrc.ec.europa.eu | Two timber skins (e.g., 44mm + 44mm or 70mm + 70mm) separated by an insulated cavity buildingtalk.com |

| Primary Insulation Source | The timber itself (limited R-value) www.researchgate.net | Integrated high-performance insulation within the wall cavity susproc.jrc.ec.europa.eu |

| Typical U-Value | 1.2–1.5 W/m²K susproc.jrc.ec.europa.eu | As low as 0.18 W/m²K susproc.jrc.ec.europa.eu |

| Year-Round Usability | Limited; prone to condensation and cold spots susproc.jrc.ec.europa.eu | High; maintains comfortable temperatures with minimal heating susproc.jrc.ec.europa.eu |

| Condensation Risk | High, leading to potential mould and timber damage link.springer.com | Low, due to thermal break and vapour barriers preventing surface and interstitial condensation link.springer.com |

The enduring strength and stability of the EV Log Cabin range are derived from a synergistic combination of premium materials, advanced manufacturing techniques, and a unique, patented joinery system with origins in Lithuania.

This holistic approach to structural integrity distinguishes Factory Cabins’ products from mass-market alternatives that often prioritize low cost over long-term durability. The foundation of this superiority lies in the meticulous selection of timber and the application of Computer Numerical Control (CNC) machining to execute a design that has been refined over years of real-world application.

This commitment to engineering excellence ensures that every cabin, from a simple EV20 to a complex multi-storey EV50, performs as a structurally sound and resilient living space.

A critical factor in the cabins’ long-term performance is the choice of timber. Factory Cabins exclusively uses slow-grown Scandinavian Spruce; a decision based on well-documented scientific principles of wood properties.

This contrasts sharply with the fast-growing Scots Pine or Eastern European Pine commonly used by competitors, which is chosen primarily for its low cost and availability.

The growing conditions in Scandinavia—characterized by long, harsh winters and short growing seasons—result in timber with tight annual rings, producing a higher density and superior dimensional stability compared to its pine counterparts.

Dimensional stability refers to a material’s ability to resist changes in shape and size due to fluctuations in moisture content, a critical attribute for any building component exposed to the UK’s variable climate.

Unstable timber, like many pines, exhibits pronounced grain patterns and higher resin content, leading to uneven shrinkage, unsightly cracking, and susceptibility to fungal blue stain. In a twin-skin cabin, where the precise alignment between the inner and outer timber skins is essential for maintaining the integrity of the insulation cavity, any warping or twisting of the logs would compromise the entire thermal and weatherproofing system.

The stability of Scandinavian Spruce ensures that the tight seals around windows, doors, and at all corners are maintained year after year, preserving the cabin’s investment in premium insulation

. It is a material choice that reflects a prioritization of longevity and performance over initial material cost.

Complementing the superior timber is the manufacturing process itself. Every component of the EV Log Cabin range is cut on state-of-the-art CNC machinery, which operates with tolerances as tight as ±0.1mm.

This level of precision is unattainable with hand-cutting methods and has profound implications for the final structure’s integrity. The CNC machines mill perfect interlocking joints, ensuring that each log fits together with microscopic accuracy, much like fine joinery rather than stacked firewood.

This eliminates the inevitable gaps that form in traditionally built cabins as the timber settles and adjusts to humidity changes, a phenomenon that compromises both thermal efficiency and weatherproofing.

Furthermore, CNC machining guarantees that every single log and component is cut to identical dimensions, ensuring consistent wall profiles and even load distribution

. This consistency is particularly vital in multi-story buildings like the EV50, where uniform stress distribution is paramount for safety and structural soundness.

The CNC process transforms the precision-engineered digital design into a physical reality with automated craftsmanship, where the engineering intent is faithfully executed in every piece.

This synergy of stable material and precise fabrication results in a structure that is exceptionally rigid, resistant to warping and settling, and built to last for decades.

The cornerstone of this structural system is the true interlocking joinery, a design pioneered by Factory Cabins in Lithuania long before such concepts became popularized online. This is not merely a stacking pattern but a mechanical locking system where each timber profile is milled to fit securely with its neighbours, providing structural integrity without relying solely on external fixings like nails or brackets.

This inherent strength allows the walls to better withstand wind loads and the natural stresses induced by temperature and moisture cycles. The longevity of this design is proven by its successful application in various timber construction projects, including luxury prefab homes, which underscores the robustness of the underlying engineering principles.

When a homeowner in Tunbridge Wells or Margate invests in an EV cabin, they are acquiring a building based on a legacy of proven innovation, not a generic design copied from an anonymous Baltic factory. The combination of Scandinavian Spruce, CNC precision, and authentic interlocking joinery creates a holistic system where each part reinforces the others, delivering a level of structural integrity that is consistently superior across all sizes and configurations within the EV range.

Practical Versatility: Transforming Garden Space into Functional Living Areas

The technical advantages of Factory Cabins’ twin-skin technology translate directly into tangible lifestyle benefits, fundamentally transforming what was once considered a seasonal novelty into a versatile, functional, and valuable extension of the home.

The ability to guarantee year-round comfort and durability unlocks a wide array of applications, catering to the evolving needs of modern UK households. From professional workspaces to passive income generators and multi-generational living solutions, the EV Log Cabin range offers a flexible platform for enhancing property utility and personal wellbeing. This versatility stems directly from the integrated design that addresses thermal comfort, acoustic separation, and service integration, making the cabin a viable living space rather than a mere storage shed.

One of the most significant outcomes of the cabin’s superior thermal performance is its capacity for year-round use. With the ability to maintain a comfortable internal temperature using minimal energy, the cabins become suitable for professional purposes even during the colder months.

This makes them ideal for use as dedicated garden offices, a demand that has surged with the rise of hybrid and remote working.

An employee in Royal Tunbridge Wells or a commuter in Folkestone can operate from a productive, draft-free workspace without being constrained by the seasons, thereby enhancing work-life balance and productivity.

Similarly, the cabins serve as secure and comfortable spaces for hobbies, fitness, or relaxation, usable throughout the year. Even for purely utilitarian purposes, such as storing classic cars or preserving sensitive documents, the stable, dry environment created by the twin-skin system is invaluable, protecting valuables from the damaging effects of humidity fluctuations.

This shift from seasonal limitation to permanent usability represents the most profound enhancement in value for the discerning homeowner.

Beyond thermal comfort, the twin-skin construction provides an incidental but highly valuable benefit: acoustic separation. The insulated cavity between the two timber skins acts as a natural sound barrier, dampening external noise.

. This feature is particularly advantageous for cabins located in areas with specific acoustic challenges, such as a garden office near a busy road in Sevenoaks or a holiday let situated close to a main thoroughfare.

The enhanced sound insulation creates a quieter, more focused environment for work or rest, improving the overall user experience.

This acoustic performance is a direct result of the dense insulation material within the cavity, demonstrating how a single design element can serve multiple functional purposes. The combination of thermal and acoustic benefits makes the cabin a truly multi-functional space, adaptable to a variety of sensory requirements.

Furthermore, the internal cavity of the twin-skin walls offers a dedicated and protected channel for integrating essential services during installation Electrical conduits for lighting and power, as well as plumbing pipes for wet rooms or kitchenettes, can be run invisibly through the wall structure.

This seamless integration avoids the need for destructive chasing and plastering of finished interiors, preserving the aesthetic integrity of the cabin’s bespoke design. This capability is crucial for creating fully-fledged living spaces, such as multi-generational accommodation for elderly parents or teenagers, which may require en-suite bathrooms or small kitchens.

The turnkey installation service offered by Factory Cabins ensures these services are incorporated correctly and safely, guided by vetted local teams who understand the cabin’s unique engineering.

This holistic approach to service integration, enabled by the cabin’s construction, elevates it from a basic shell to a complete, habitable unit ready for immediate occupation. The combination of thermal comfort, acoustic privacy, and streamlined service provision empowers homeowners to customize their EV cabin for virtually any purpose, maximizing the return on their investment in both time and money.

Market Differentiation: Authenticity and Value Through Direct Manufacturing

Factory Cabins’ position in the UK garden building market is strategically defined not only by its superior product but also by its transparent business model and authentic heritage as the original designer of its signature interlocking systems. This approach directly confronts and debunks common market misconceptions, particularly the notion that “British-made” implies superior quality.

By clarifying its Lithuanian origins and championing a direct-from-source manufacturing model, the company positions itself as the purveyor of authentic, engineered solutions, cutting out the layers of markups and rebranding that characterize the practices of many UK-based competitors.

This strategy builds a powerful narrative of integrity and value, appealing to discerning homeowners in Sussex and Kent who seek long-term performance over fleeting marketing claims.

A central pillar of the brand’s identity is its status as a pioneer of interlocking timber construction. Before the term “log cabin” became a ubiquitous cliché in UK garden centres, Factory Cabins was developing and refining the precise joinery systems that now define structural integrity in the industry.

This heritage is leveraged to establish authority and prove authentici. When customers see strikingly similar designs on competitor websites, they are often looking at copies of Factory Cabins’ original engineering archives, which were built over twenty years of iterative development and real-world testing. By being transparent about this origin story, Factory Cabins answers the implicit question of “why should I believe you?” with a history of genuine innovation.

This reframes the conversation from a simple product comparison to a discussion of provenance and engineering pedigree, distinguishing the company from resellers who import generic kits and apply their own branding. This authenticity provides a sense of security and confidence that is absent when purchasing a product whose true origins are obscured.

The second strategic advantage is the direct-from-source pricing model. Many UK companies claiming to be “manufacturers” are, in fact, importers who purchase container loads of pre-cut kits from overseas factories, add their branding, and sell them at prices inflated by their own operational overheads. These costs include showroom rentals, sales commissions, warehousing, and general administrative expenses, none of which contribute to the quality of the cabin itself. Factory Cabins bypasses this entire intermediary chain. By manufacturing the cabins in its Lithuanian facility and shipping them directly to customers in Sussex and Kent, the company eliminates the importer’s margin, the distributor’s markup, and the retailer’s overhead.

This allows the customer’s investment to flow directly into the quality of the materials—premium Scandinavian Spruce—and the precision of the craftsmanship, delivered via CNC machinery.

This model delivers a clear and compelling value proposition: access to high-quality, European-engineered cabins at prices that undercut those of UK-branded competitors who are simply reselling the same or similar products with a significant price premium for their branding and middleman services.

The case study comparing the total long-term cost of ownership between a cheap, imported single-skin cabin and a well-engineered twin-skin cabin powerfully illustrates this principle, showing that while the upfront cost may be higher, the twin-skin cabin delivers exponentially greater utility and avoids costly remedial work.In conclusion, the differentiation of the EV Log Cabin range is a multi-faceted achievement grounded in superior engineering, authentic heritage, and a transparent business model. The twin-skin interlocking system provides a demonstrable advantage in thermal performance, ensuring year-round usability where competitors fail. This is achieved through the intelligent use of stable Scandinavian Spruce, fabricated with CNC precision, and assembled using a patented joinery system born from years of innovation in Lithuania.

This technical foundation translates into unparalleled versatility, transforming garden space into a functional asset for work, leisure, or investment. Strategically, Factory Cabins leverages its origin story to build trust and authenticity, challenging the misleading narratives of the market. Its direct-from-source model delivers this superior product at a fair price, free from the markups associated with rebranding and unnecessary intermediaries.

For the discerning homeowner in Sussex, Kent, or beyond, choosing a Factory Cabins EV Log Cabin range is a decision rooted in value, performance, and integrity—a choice to acquire a building engineered to last, not one designed for disposability.

Please send us an email to sales@factorycabins.com

or call 0208 226 5164

Lastly and most importantly.

Why Buying Direct From the Mill Isn’t Turnkey (And Why That’s Actually Better For You)

In the log cabin industry, there’s a critical distinction that most suppliers deliberately blur: the difference between a true turnkey solution and buying directly from the manufacturer. Many UK-based companies present themselves as “turnkey providers” while actually functioning as importers who add multiple layers of markup to generic Baltic imports. But when you buy directly from the mill—like Factory Cabins in Lithuania—you’re accessing something fundamentally different: pure manufacturing value without the middleman markup, with complete customization control. Let’s clarify why this model isn’t technically “turnkey” (in the conventional sense) and why that’s precisely what makes it superior for discerning customers across Sussex and Kent.

The Turnkey Myth: What Most Suppliers Actually Deliver

When a UK garden centre or online retailer promises a “turnkey” log cabin solution, what they’re really offering is a package that includes:

- A generic, mass-produced cabin shipped from a Baltic factory

- A basic assembly service (often by subcontracted laborers with minimal cabin expertise)

- Limited customization options (typically just choosing from pre-configured sizes)

- A significant markup for their “branding” and “service”

This isn’t true turnkey—it’s turnkey theater. The cabin wasn’t designed for your specific needs. The assembly team has never seen your exact model before. The “customization” is merely selecting from a few pre-determined options. And you’re paying 40-60% more for the privilege of having a UK company’s logo on the brochure.

True turnkey should mean: “We handle everything from design through installation, tailored specifically to your requirements.” But when suppliers import generic cabins and apply superficial branding, they can’t deliver genuine customization—they’re selling containers of pre-cut kits, not bespoke solutions.

The Mill-Direct Advantage: Your Blueprint, Our Precision

When you buy directly from Factory Cabins’ Lithuanian manufacturing facility, you’re engaging with the actual engineers and craftsmen who pioneered interlocking log cabin technology. This direct relationship creates three fundamental advantages that generic “turnkey” suppliers cannot match:

1. Elimination of All Middleman Markup

By purchasing at the source—where the CNC machinery cuts the Scandinavian spruce—you eliminate three costly layers:

- The importer’s margin (typically 20-25%)

- The distributor’s markup (15-20%)

- The retailer’s overhead (20-30%)

These aren’t hypothetical numbers. Consider this real comparison: A 4m x 5m “British-made” cabin advertised at £12,500 from a Tunbridge Wells garden centre is likely a rebranded Baltic import with a £4,000-£5,000 markup for UK branding. The same quality, directly from our mill, costs approximately £7,800-£8,200 with genuine customization included.

This isn’t about paying less for the same product—it’s about paying appropriately for superior engineering without paying for empty branding. When you buy direct from the mill, every pound you spend goes toward premium materials (Scandinavian spruce, not pine), precision CNC machining, and authentic interlocking joinery—not toward maintaining a UK showroom or sales team commissions.

2. True Customization: Building to Your Specifications, Not Their Inventory

Most “customizable” cabins from UK suppliers are merely choosing from pre-cut inventory. They might offer “three window positions” or “two door options,” but these are predetermined configurations designed to fit within shipping containers—not your actual needs.

When you work directly with the manufacturer, you’re not selecting from limited options. You’re collaborating with the engineers who created the interlocking system to design a cabin that fits your space perfectly. This means:

- Window and door placement exactly where you need them (not where shipping constraints dictate)

- Insulation levels tailored to your specific use (a garden office in Brighton requires different thermal performance than a holiday let in Margate)

- Structural adaptations for challenging sites (sloping gardens, conservation area restrictions, coastal exposure)

- Interior layout designed around your workflow (not compromised to fit standard panel sizes)

Our EV Log Cabin range isn’t a series of pre-determined models—it’s a flexible system where every component is CNC-machined to your specifications after you order. Want an angled window to capture a view of the South Downs? Need higher ceilings for a yoga studio in Tunbridge Wells? Require reinforced flooring for heavy equipment? These aren’t “special requests”—they’re standard when you work directly with the manufacturer.

3. The Twin-Skin Difference: Engineering Choice, Not Marketing Hype

This is where buying direct becomes essential for quality. Many UK suppliers claim “insulated cabins” while actually selling single-skin structures with superficial insulation added later. The difference between genuine twin-skin construction and these compromised alternatives is profound—but only visible to those who understand the engineering.

When you work directly with the manufacturer, you’re not choosing between marketing terms. You’re making an informed decision between:

- True twin-skin construction: Two independent 44mm or 70mm spruce skins with an insulated cavity (U-value as low as 0.18 W/m²K)

- Single-skin alternatives: Solid timber walls (typically 44mm or 70mm) with afterthought insulation (U-value 1.2-1.5 W/m²K)

Most UK suppliers don’t even understand this distinction—they’re selling what their Baltic importer provides. But when you work directly with the mill, you can specify exactly which system meets your needs. Need a seasonal garden shed? A single-skin cabin might suffice. Want year-round usability as a garden office or holiday let? Twin-skin is non-negotiable. The choice is yours—not predetermined by what fits in a shipping container.

Why This Isn’t “Turnkey” (And Why That Matters)

Technically, buying direct from the mill isn’t turnkey because it requires your involvement in the design process. You’re not just signing a contract and waiting for installation day—you’re actively shaping the final product. But this “inconvenience” is precisely what delivers superior value:

- No compromise on design: You’re not fitting your needs to pre-determined models

- No hidden costs: What you see in the design phase is what you get—no “optional extras” added during installation

- Direct accountability: When issues arise (rare with our cabins), you speak directly with the engineers who designed it—not a call center reading from scripts

The turnkey model creates a dangerous illusion of simplicity. You think you’re getting a hassle-free solution, but you’re actually surrendering control to intermediaries who prioritize their profit margins over your specific requirements. When the cabin leaks in winter or the windows stick, who takes responsibility? The installer blames the importer, who blames the manufacturer. With direct purchasing, accountability is absolute: we designed it. We cut it. We deliver it. We stand behind it.

The Lithuanian Advantage: Where Innovation Meets Integrity

Our location in Lithuania isn’t a disadvantage—it’s your quality assurance. Before “log cabin” became a garden centre cliché, our engineers were pioneering the interlocking systems now copied across the internet. We’ve refined these designs through decades of real-world testing in climates far harsher than Britain’s—ensuring performance that exceeds UK standards.

When UK companies claim “British-made” for rebranded Baltic imports, they’re trading on your trust while delivering compromised value. But by working directly with the source—the actual pioneers of interlocking log technology—you gain:

- Authentic engineering: No degraded copies of our original designs

- Material integrity: Scandinavian spruce, not fast-grown pine with high resin content

- Precision manufacturing: CNC tolerances of ±0.1mm, not hand-cut approximations

- Transparent pricing: No markup for “British” branding on imported products

This isn’t about geography—it’s about authenticity. The finest cabins for sale in Sussex and Kent don’t carry British labels. They carry Lithuanian engineering and the quiet confidence of knowing you’ve bought from the source, not the seller.

Your Cabin, Your Way: From Brighton to Margate

Whether you’re in coastal Kent facing salt-laden winds or in the clay soils of the Weald, your garden building needs are unique. Generic “turnkey” solutions can’t address these nuances—they’re designed for shipping efficiency, not your specific requirements.

When you buy directly from Factory Cabins’ mill:

- Sussex coastal properties get stainless hardware and stable spruce that withstands salt air better than pine alternatives

- Kent conservation areas receive designs that comply with local restrictions while maintaining structural integrity

- Tunbridge Wells professionals get garden offices with service cavities for seamless electrical integration

- Margate holiday let investors receive cabins engineered for year-round bookings with genuine thermal performance

This level of specificity isn’t possible with turnkey suppliers who treat all sites as interchangeable. It requires direct collaboration between you and the manufacturer—where your requirements shape the design, not the other way around.

The Bottom Line: Value Flows From Source to Site

The log cabin industry thrives on obfuscation: hiding origins, inflating specifications, rebranding imports as “British.” This model serves suppliers—not customers. It creates a cycle where structures fail quickly, forcing replacement rather than delivering decades of service.

By purchasing directly from the mill, you bypass this entire system. You gain:

- Authentic engineering from the pioneers of interlocking design

- Transparent pricing without middleman markups

- True customization tailored to your specific needs

- Direct accountability from the actual manufacturer

This isn’t turnkey in the conventional sense. It’s better. It’s source-direct: where your vision meets our precision engineering, creating a cabin that’s not just installed, but truly yours. From Brighton’s seafront to Margate’s coastline, your garden deserves better than compromise. It deserves a cabin built to your specifications—not one designed for container shipping.

When you work directly with Factory Cabins, you’re not buying a product. You’re commissioning a solution engineered specifically for you, at a price that reflects genuine value rather than layered markups. That’s not turnkey—it’s the superior alternative.

Please send us an email to sales@factorycabins.com

or call 0208 226 5164