Beyond the Roadblock: How Twin-Skin Log Cabins Revolutionize Construction in Inaccessible Locations

When Traditional Building Methods Hit a Dead End

Imagine standing on the edge of your dream property—a secluded lakeside plot, a forested hilltop, or a narrow coastal strip—and realizing that your vision for a quality insulated building is impossible. Not because of planning restrictions or budget constraints, but because there’s simply no way to get construction materials to the site.

No road access. No vehicle pathway. No conventional building method can reach your location. For decades, this scenario has left homeowners with two unpalatable choices: abandon their vision or settle for inferior, temporary structures that fail to deliver genuine year-round usability.

This is where the limitations of traditional construction methods become painfully apparent. Conventional brick-and-mortar construction requires extensive site preparation, heavy machinery, and multiple delivery trips with materials that simply cannot be transported to challenging locations.

Even standard timber frame construction—often marketed as “flexible”—requires multiple visits from skilled laborers and specialized equipment that cannot navigate tight spaces or water barriers. When accessibility becomes the primary constraint, most building solutions fail before they even begin.

But what if there was a way to bypass these limitations entirely? What if you could deliver a fully insulated, high-performance building to virtually any location—regardless of terrain or access constraints? This is the revolutionary promise of twin-skin log cabin technology, a solution that transforms previously impossible building sites into reality while delivering superior thermal performance at a fraction of the conventional construction cost.

The Accessibility Advantage: Reaching the Unreachable

The most transformative aspect of twin-skin log cabin construction isn’t merely its thermal performance—it’s the ability to access locations that conventional building methods simply cannot reach. This capability stems from the fundamental design of the twin-skin system, which allows for modular delivery and assembly in even the most challenging environments.

Consider the case of the Harrison family in the Lake District, who dreamed of creating a lakeside entertainment space on their 2.5-acre property overlooking Windermere. Their idyllic location presented significant obstacles:

- No vehicular access: The only route to the desired building site was across a narrow strip of water

- Environmental restrictions: The property sits within an Area of Outstanding Natural Beauty with strict building regulations

- Year-round usability requirement: They wanted a space that could be enjoyed in all seasons, not just summer

- Structural challenges: The lakeside terrain featured unstable soil that would have required expensive foundation work for conventional construction

Traditional building methods were immediately ruled out. Brick-and-mortar construction would have required extensive site preparation, temporary road construction across sensitive terrain, and months of disruptive work. Portable buildings lacked the insulation and quality they desired for year-round use. Even standard single-skin log cabins would have struggled with the damp lakeside environment and failed to deliver the thermal performance needed for winter gaming sessions.

What they needed was a solution that combined structural integrity with genuine insulation performance, delivered in a way that respected both the environment and their challenging site access. The answer was clear: a fully insulated twin-skin log cabin, engineered for British weather and designed specifically for their unique requirements.

Unlike conventional construction that requires multiple material deliveries and heavy machinery, our twin-skin log cabins arrive as a single, coordinated shipment. Every component is pre-cut and pre-engineered at our Lithuanian manufacturing facility, then packaged for efficient transport. For the Harrison family’s lakeside location, we designed the cabin in modular sections that could be safely transported by boat:

- Pre-assembled wall sections: Two-person manageable sizes that maintained structural integrity

- Waterproof packaging: Each component sealed against lake moisture during transit

- Sequential delivery plan: Components organized in precise assembly order to minimize on-site handling

This modular approach—only possible because of our direct manufacturing control—turned what could have been a logistical nightmare into a smooth operation. The entire cabin was delivered in three boat trips, with assembly beginning immediately upon arrival of the first components.

The Real Cost of Inaccessibility: When Conventional Construction Fails

The inability to access challenging building sites isn’t just a logistical inconvenience—it’s a significant economic barrier that prevents homeowners from realizing the full potential of their properties. When traditional construction methods hit accessibility limitations, homeowners face several costly consequences:

Compromised Design and Functionality

Without the ability to deliver conventional building materials to challenging locations, homeowners often settle for inferior structures that fail to meet their actual needs. Instead of a properly insulated, year-round usable space, they’re forced to accept seasonal sheds or poorly constructed temporary structures that require constant maintenance and cannot be used during winter months.

Extended Project Timelines

Conventional construction in difficult locations often requires extensive site preparation before any building can begin. This preparation phase—clearing paths, creating temporary access routes, or installing specialized equipment—can add weeks or even months to project timelines, significantly delaying the realization of the homeowner’s vision.

Environmental Impact

The extensive site preparation required for conventional construction often causes significant environmental disruption. Creating temporary roads through sensitive ecosystems, disturbing soil stability, or altering natural drainage patterns can have lasting impacts on the environment—impacts that many homeowners seeking natural retreats specifically want to avoid.

Cost Overruns

The hidden costs of conventional construction in challenging locations are substantial. Specialized equipment rentals, additional labour for site preparation, extended project timelines, and potential environmental mitigation measures can easily double or triple the initial project estimate.

Compromised Quality

Perhaps most damaging is the inevitable compromise on quality when conventional construction methods are adapted to challenging sites. Builders often cut corners on materials, insulation, or structural elements to accommodate accessibility constraints, resulting in buildings that fail to deliver the promised performance or longevity.

For homeowners seeking a quality insulated building, these consequences are particularly devastating. They’ve invested significant resources in finding the perfect location only to discover that the very features that make the property special—its seclusion, natural beauty, or unique terrain—become barriers to construction. The result is a cycle of disappointment where dreams are deferred or compromised, and the full potential of the property remains unrealized.

Twin-Skin vs. Conventional Construction: The Structural Difference That Matters

To understand why twin-skin log cabins succeed where conventional construction fails, we must examine the fundamental structural differences between these approaches. The key distinction lies not just in the materials used, but in the engineering philosophy that drives the design.

Conventional Timber Frame Construction: The Layered Approach

Traditional timber frame construction follows a sequential, on-site assembly process that requires multiple visits from skilled laborers and specialized equipment:

- Foundation work: Often requiring heavy machinery and extensive site preparation

- Frame construction: Multiple trips to deliver and assemble structural components

- Insulation installation: Additional visits to add insulation materials

- Exterior cladding: Further deliveries and labour for weatherproofing

- Interior finishing: Final trips for internal walls, flooring, and services

This layering approach creates multiple points of vulnerability. Each stage depends on the previous one being completed correctly, and any delay or issue at one stage impacts the entire project. In challenging locations, this sequential process becomes particularly problematic—each delivery requires navigating the same access constraints, multiplying the logistical challenges.

Most critically, the insulation in conventional timber frame construction is typically added as an afterthought—a layer sandwiched between structural elements. This approach creates thermal bridges at structural junctions, compromises the integrity of the insulation layer, and makes it difficult to achieve consistent thermal performance throughout the building.

Twin-Skin Log Cabin Construction: The Integrated Approach

In contrast, twin-skin log cabin construction follows an integrated design philosophy where all elements work together from the outset:

- Single manufacturing process: All components are precision-cut and assembled at the factory

- Modular delivery: Pre-engineered sections designed for efficient transport

- Rapid assembly: Minimal on-site labour with standardized connections

- Integrated insulation: Thermal performance built into the wall structure from the beginning

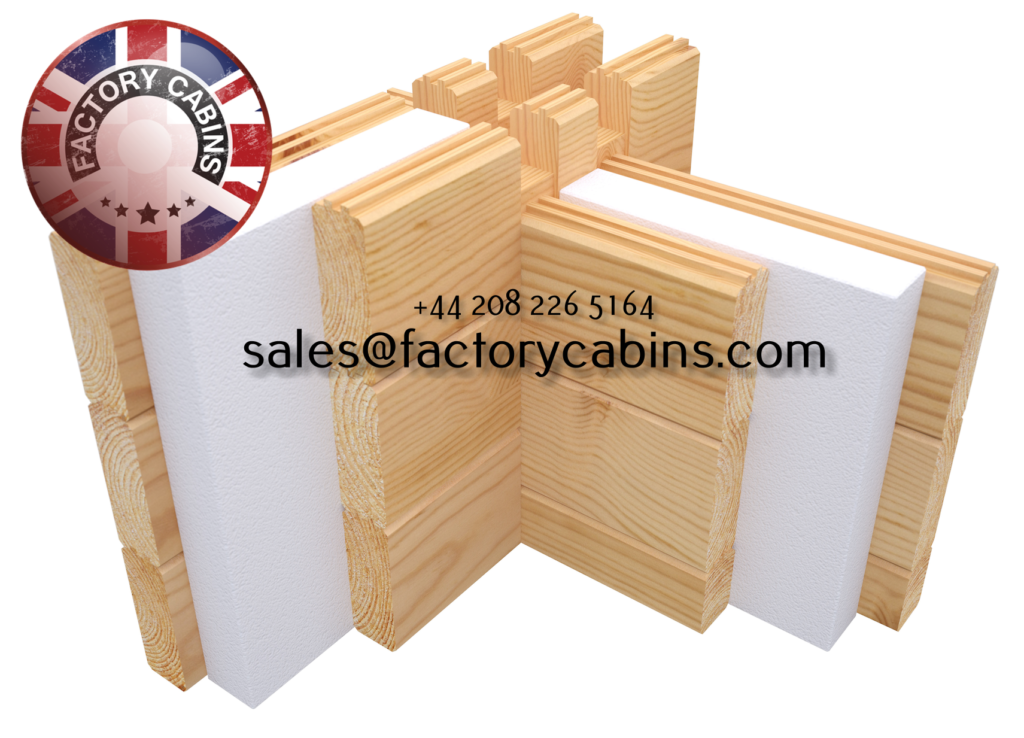

The twin-skin design features two independent skins of premium Scandinavian spruce, separated by a precisely engineered cavity filled with high-grade insulation. This cavity is not an afterthought—it’s a fundamental component of the wall structure, designed to deliver optimal thermal performance while maintaining structural integrity.

This integrated approach is particularly advantageous in challenging locations because it eliminates the need for multiple material deliveries and sequential construction stages. Every component arrives ready for immediate assembly, reducing on-site time and labour requirements to a minimum.

The Insulation Advantage: Engineering Flexibility Where It Matters Most

One of the most significant advantages of twin-skin log cabin construction is the inherent flexibility of the insulation system. Unlike conventional construction where adding more insulation requires complex modifications to the structural design, the twin-skin system allows for simple, scalable insulation adjustments that directly address the specific needs of challenging locations.

The Conventional Insulation Dilemma

In traditional timber frame construction, increasing insulation levels presents significant challenges:

- Structural modifications: Additional insulation often requires thicker wall sections, which may not fit within existing structural constraints

- Thermal bridging: Conventional construction methods create inevitable thermal bridges at structural junctions, reducing the effectiveness of added insulation

- Moisture management: Adding insulation without proper vapor barriers can create moisture traps that lead to condensation and timber degradation

- Cost inefficiency: The marginal cost of adding insulation often becomes prohibitively high as insulation levels increase

These limitations mean that conventional construction typically caps at a certain insulation level—sufficient for standard applications but inadequate for challenging locations with extreme weather conditions or specific usability requirements.

The Twin-Skin Insulation Solution

With twin-skin log cabin construction, insulation becomes a simple matter of adjusting the cavity size between the two timber skins. The system is designed from the outset to accommodate variable insulation levels without compromising structural integrity:

- Scalable cavity design: The space between the two timber skins can be expanded to accommodate additional insulation

- Continuous thermal barrier: The insulation cavity creates a seamless thermal break that eliminates thermal bridging

- Integrated moisture management: The design incorporates vapor barriers and moisture control systems as part of the wall structure

- Cost-effective scaling: Increasing insulation levels requires minimal additional cost compared to conventional methods

This flexibility is particularly valuable for challenging locations where specific insulation requirements may vary significantly. For example:

- Coastal properties: Require enhanced moisture management systems to combat salt air

- High-altitude locations: Need increased insulation to handle extreme temperature variations

- Forest settings: May require additional insulation to maintain consistent interior temperatures

Our 70mm x 70mm interlocking system demonstrates this flexibility perfectly. The standard configuration features a cavity designed for optimal insulation performance in most UK conditions.

However, for locations requiring enhanced thermal performance—such as lakeside properties in the Lake District or coastal sites in Kent—the cavity can be expanded to accommodate 100mm or even 300mm of high-performance insulation.

This scalability means that twin-skin log cabins can be precisely engineered for the specific thermal requirements of each location, delivering optimal performance without the cost inefficiencies of conventional construction methods.

The Cost Equation: Why Twin-Skin Delivers Better Value

When evaluating construction options for challenging locations, cost is often the primary consideration. However, a true cost analysis must go beyond the initial price tag to consider the total value delivered over the building’s lifetime. When viewed through this lens, the twin-skin log cabin approach consistently demonstrates superior value.

Conventional Construction Cost Structure

Conventional construction in challenging locations follows a cost structure that becomes increasingly inefficient as accessibility constraints increase:

- Site preparation costs: Often exceed 20-30% of total project cost for difficult locations

- Multiple delivery costs: Each material delivery incurs additional transportation costs

- Extended labour costs: longer project timelines increase labour expenses

- Compromise costs: Quality compromises to accommodate access constraints often lead to higher maintenance costs

The marginal cost of addressing accessibility challenges in conventional construction is high and non-linear—each additional constraint multiplies the cost rather than adding it incrementally.

Twin-Skin Cost Structure

The twin-skin log cabin approach follows a fundamentally different cost structure that remains efficient regardless of accessibility constraints:

- Single delivery cost: All components arrive in one coordinated shipment

- Minimal site preparation: Often requiring only a simple foundation system

- Rapid assembly cost: Reduced labour time and specialized equipment needs

- Integrated insulation cost: Additional insulation requires minimal cost increase

The marginal cost of addressing accessibility challenges in twin-skin construction is low and linear—each additional constraint adds a predictable, manageable cost rather than multiplying expenses.

This difference becomes particularly apparent when comparing insulation options. In conventional construction, increasing insulation levels often requires significant structural modifications that can double or triple costs. In twin-skin construction, increasing the cavity size between the 70mm x 70mm interlocking logs to accommodate 100mm or 300mm of insulation adds minimal cost while delivering substantial thermal performance benefits.

Real-World Applications: Twin-Skin Solutions in Challenging Locations

The accessibility advantages of twin-skin log cabin construction are not theoretical—they’re being demonstrated daily across the UK in locations where conventional construction would be impossible or prohibitively expensive.

Lakeside Retreats: Where Water Is the Only Access Route

For property owners with lakeside plots like the Harrison family, the twin-skin approach provides a solution that respects both the environment and the vision. By designing modular sections that can be transported by boat, we’ve created numerous lakeside retreats that would have been impossible with conventional construction.

These cabins feature:

- Water-resistant construction: Marine-grade hardware and corrosion-resistant materials

- Elevated foundation options: Minimizing environmental impact while providing stable support

- Enhanced insulation: For year-round comfort despite the damp lakeside environment

- Flexible layout options: Allowing for optimal use of the limited accessible space

Forest Clearings: Where Trees Block Conventional Access

In heavily wooded areas, twin-skin log cabins offer a solution that minimizes environmental disruption while delivering high-performance structures. Rather than clearing wide paths for construction equipment, we can deliver pre-engineered sections through narrow forest trails.

These forest cabins feature:

- Minimal footprint design: Reducing the need for extensive site clearing

- Adaptable foundation systems: Allowing for installation on uneven terrain

- Natural integration: Wood finishes that blend with forest surroundings

- Enhanced insulation: For consistent interior temperatures despite forest microclimates

Coastal Properties: Where Salt Air Demands Superior Protection

Coastal locations present unique challenges with salt-laden air that accelerates corrosion and requires specialized materials. Twin-skin log cabins provide a solution that combines structural integrity with environmental resilience.

These coastal cabins feature:

- Marine-grade hardware: Stainless steel components resistant to salt corrosion

- Enhanced moisture management: Integrated systems to prevent salt-induced damage

- Specialized finishes: Protecting wood from the harsh coastal environment

- Optimized insulation: For consistent comfort despite coastal temperature fluctuations

The Quality Imperative: Why Twin-Skin Delivers Genuine Performance

For homeowners seeking a quality insulated building, the difference between twin-skin and conventional construction isn’t just about accessibility—it’s about genuine performance. When you choose a twin-skin log cabin, you’re not just solving an access problem; you’re investing in a building that delivers superior thermal performance, structural integrity, and longevity.

Thermal Performance: The Defining Difference

The most immediate benefit of twin-skin construction is its superior thermal performance. While conventional construction struggles to achieve U-values below 0.30 W/m²K (the current UK building standard), our twin-skin systems deliver U-values as low as 0.18 W/m²K—significantly better than modern residential construction.

This performance difference translates directly into:

- Year-round usability: Spaces that remain comfortable in winter without excessive heating

- Reduced energy costs: Minimal energy requirements for maintaining comfortable temperatures

- Moisture control: Elimination of condensation issues that plague conventional structures

- Long-term durability: Protection of timber structure from moisture-related damage

Structural Integrity: Built to Last

The interlocking design of twin-skin log cabins provides exceptional structural integrity that conventional construction cannot match. Our precision-engineered joints create a structure that:

- Resists wind loads: Critical for exposed locations like coastal properties

- Minimizes settlement issues: The interlocking system maintains integrity as timber adjusts to environmental changes

- Distributes stress evenly: Preventing weak points that develop in conventional construction

- Maintains thermal performance: Structural integrity is essential for maintaining the insulation cavity’s integrity

Longevity: A Building That Improves with Age

Perhaps most importantly, twin-skin log cabins deliver genuine longevity that conventional construction often fails to achieve. The combination of premium materials, precision engineering, and integrated moisture management creates a structure that:

- Requires minimal maintenance: Unlike conventional structures that need regular repairs

- Improves with age: Properly maintained wood structures develop a beautiful patina over time

- Retains value: High-quality log cabins often appreciate as they age

- Sustains performance: Thermal and structural performance remains consistent for decades

The Future of Construction: Accessibility as a Design Priority

As we look to the future, the importance of accessibility in building design will only increase. With growing environmental awareness and stricter regulations on site disruption, construction methods that minimize environmental impact while delivering high-performance buildings will become increasingly valuable.

Twin-skin log cabin technology represents a significant step forward in this evolution. By designing buildings that can access challenging locations with minimal disruption, we’re not just solving today’s construction problems—we’re creating a model for sustainable building practices that will become increasingly important in the coming decades.

This approach aligns perfectly with the growing demand for:

- Sustainable construction: Minimizing environmental impact while delivering high-performance buildings

- Adaptive design: Creating buildings that respond to specific site conditions rather than forcing sites to conform to standard construction methods

- Resilient infrastructure: Building structures that can withstand extreme weather events and environmental changes

- Resource efficiency: Maximizing the value of materials through precision engineering and minimal waste

Conclusion: Beyond Access—Creating Possibility

The true power of twin-skin log cabin construction extends far beyond solving accessibility challenges. It represents a fundamental shift in how we approach building design—a shift from forcing sites to conform to construction methods to designing construction methods that conform to site requirements.

For the homeowner with a dream location that conventional construction methods cannot reach, this shift means the difference between compromise and realization. It means transforming previously impossible sites into valuable, functional spaces that enhance property value and quality of life.

When you choose a twin-skin log cabin from Factory Cabins, you’re not just buying a building—you’re investing in a solution that:

- Respects your site: Minimizing environmental disruption while maximizing space utilization

- Delivers genuine performance: Providing year-round usability with superior thermal performance

- Offers genuine value: Delivering high-quality construction at a reasonable cost

- Solves real problems: Addressing accessibility constraints that conventional methods cannot overcome

The journey from inaccessible dream to realized reality begins with understanding that sometimes, the most significant barrier isn’t the terrain—it’s the construction method. By choosing a twin-skin log cabin solution, you’re not just building a structure—you’re creating possibility where none existed before.

Ready to transform your inaccessible dream site into a reality? Contact Factory Cabins today for a consultation on how our twin-skin log cabin technology can reach locations that conventional construction cannot. From Brighton to Margate and beyond, we deliver quality, accessibility, and performance that redefine what’s possible in garden building.

Please send us an email to sales@factorycabins.com

or call 0208 226 5164