The Lakeside Game Room Retreat, Residential Bespoke Twin-Skin Log Cabin Transformation

When Space Constraints Meet Creative Vision: How Residential Twin Skin Log Cabins Delivered a Premium Living Space Where Traditional Construction Couldn’t Reach!

How do you create the ultimate gaming and entertainment space when your property sits on a secluded lakeside plot with no road access? For the Harrison family in the Lake District, this wasn’t just a logistical challenge—it was a test of what modern log cabin engineering could truly achieve. The answer lay in a bespoke Country Range Twin-Skin Log Cabin, carefully ferried across the water to create a stunning new entertainment hub that has transformed their family gatherings and weekend get-togethers.

BS3632 Certified Residential Park Homes with Unmatched Twin-Skin Durability

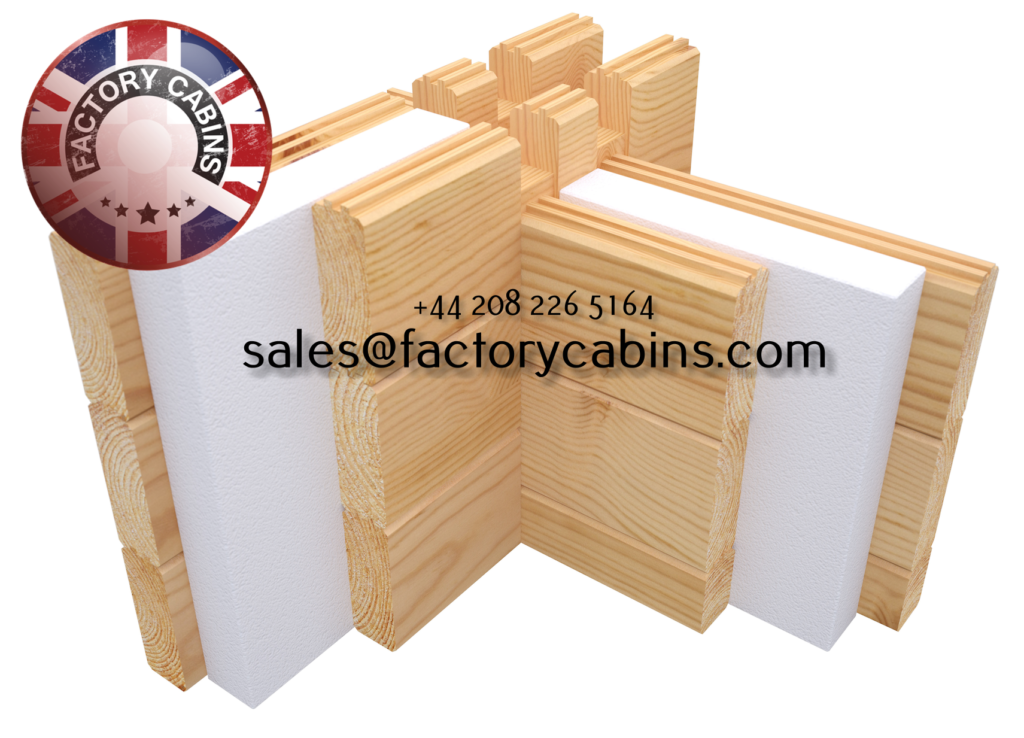

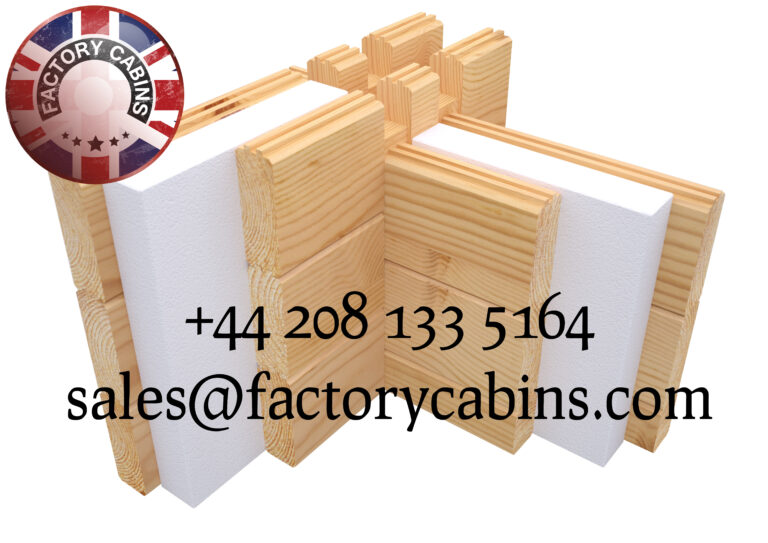

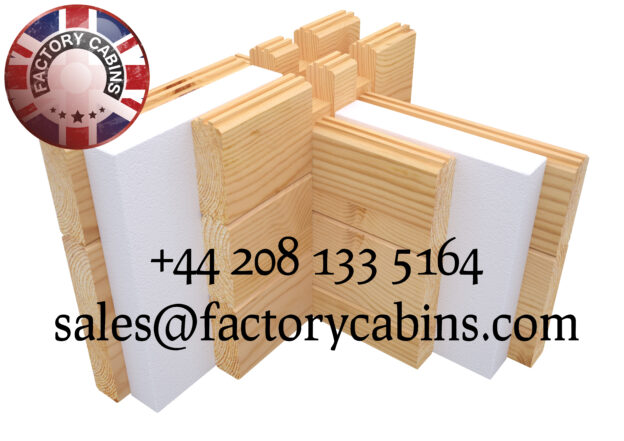

Our residential park homes exceed BS3632 standards—the rigorous British specification for permanent park home construction. Engineered with premium twin-skin technology, these structures feature dual layers of Scandinavian spruce with integrated insulation that delivers exceptional thermal performance (U-values as low as 0.18 W/m²K). This isn’t just weather resistance—it’s weather defiance. From coastal salt winds to inland temperature extremes, our precision-engineered interlocking system maintains structural integrity while preventing condensation and thermal bridging. CNC-machined to ±0.1mm tolerances with joinery-grade glulam windows and 28mm reinforced glass, these homes withstand decades of British weather without compromise. When mother nature tests your investment, our BS3632-certified twin-skin homes don’t just survive—they thrive.

This isn’t just another log cabin story. It’s a testament to how purpose-built, fully insulated twin-skin log cabins are solving space challenges that traditional construction methods simply cannot address. From Brighton to the Lake District, homeowners are discovering that when standard building approaches hit limitations, the innovative engineering of interlocking log cabin systems provides the solution.

The Challenge: Creating Entertainment Space Where Conventional Building Failed

The Harrisons had long dreamed of creating a dedicated games and entertainment space on their 2.5-acre property overlooking Windermere. Their vision included a comfortable area for board games, a pool table, comfortable seating, and even space for occasional overnight guests—a true multi-functional retreat from their main home.

However, their idyllic lakeside location presented significant obstacles:

- No vehicular access: The only route to the desired building site was across a narrow strip of water

- Environmental restrictions: The property sits within an Area of Outstanding Natural Beauty with strict building regulations

- Year-round usability requirement: They wanted a space that could be enjoyed in all seasons, not just summer

- Structural challenges: The lakeside terrain featured unstable soil that would have required expensive foundation work for conventional construction

Traditional building methods were immediately ruled out. Brick-and-mortar construction would have required extensive site preparation, temporary road construction across sensitive terrain, and months of disruptive work. Portable buildings lacked the insulation and quality they desired for year-round use. Even standard single-skin log cabins would have struggled with the damp lakeside environment and failed to deliver the thermal performance needed for winter gaming sessions.

What they needed was a solution that combined structural integrity with genuine insulation performance, delivered in a way that respected both the environment and their challenging site access. The answer was clear: a fully insulated twin-skin log cabin from our Country Range, engineered for British weather and designed specifically for their unique requirements.

The Design Process: Bespoke Solutions for Unique Entertainment Needs

When the Harrisons contacted Factorycabins.com, they weren’t just looking for a standard cabin. They were seeking a custom entertainment space that would become the heart of their family gatherings. Our design team worked closely with them to create a solution that would exceed expectations while working within their constraints.

Understanding the Vision

The initial consultation revealed several key requirements:

- Space for a full-sized pool table with comfortable clearance

- Ample natural light without compromising insulation

- Year-round comfort for both daytime gaming and occasional overnight stays

- Integration with the natural lakeside setting

- Minimal environmental impact during installation

What made this project particularly interesting was the family’s desire to create a space that could serve multiple functions: a quiet board game area for adults, an energetic games room for teenagers, and occasionally, additional sleeping accommodation for guests. This multi-purpose requirement demanded thoughtful layout planning and flexible design elements.

The Country Range Twin-Skin Advantage in Design

From the outset, it was clear that only a twin-skin insulated log cabin would meet their year-round usability goals. While single-skin cabins might suffice for summer use, the Lake District’s damp, cool climate demands genuine thermal performance.

Our Country Range Twin-Skin system provided the perfect foundation. The innovative double-wall technology creates a continuous thermal barrier that maintains comfortable interior temperatures with minimal energy input. Unlike conventional cabins where insulation is added as an afterthought, our twin-skin design integrates high-performance insulation directly into the wall structure, achieving U-values as low as 0.18 W/m²K—significantly better than standard UK building regulations require.

This wasn’t merely about staying warm in winter. The consistent interior temperature also prevented condensation, a critical consideration for a lakeside location where humidity levels remain high year-round. For a space housing expensive gaming equipment and furniture, this moisture control was essential.

Customisation for Gaming Excellence

The beauty of working directly with the manufacturer (rather than through a middleman) was the ability to tailor every element to the Harrisons’ specific needs:

- Window placement: Strategically positioned to maximize natural light on the pool table while minimizing glare

- Interior layout: A flexible partition system allowing the space to transform from open gaming area to private sleeping quarters

- Electrical planning: Integrated wiring channels for lighting, sound systems, and charging stations, all concealed within the insulated cavity

- Acoustic considerations: The twin-skin construction naturally dampens sound, preventing game noise from disturbing the main house

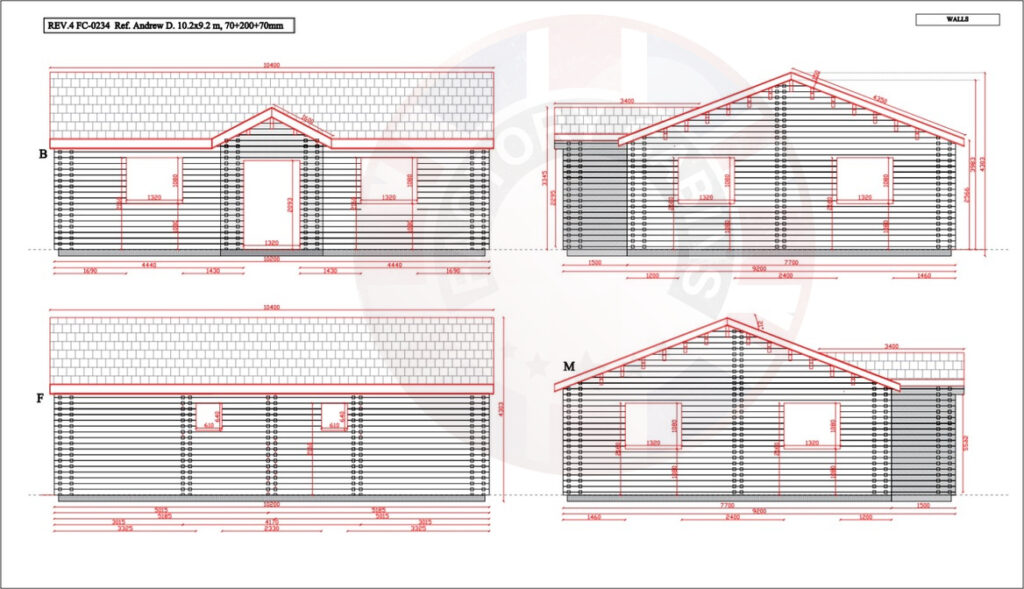

Most importantly, the Harrisons didn’t have to compromise on size. Our Country Range offers everything from compact 20m² game rooms to expansive 50m² multi-functional spaces. For their lakeside location, we recommended a 36m² twin-skin design—spacious enough for all their requirements yet compact enough to maintain efficient heating.

The Manufacturing Process: Precision Engineering for Challenging Sites

While many suppliers would have struggled with the Harrisons’ inaccessible site, our manufacturing approach turned this challenge into an opportunity to showcase the advantages of precision-engineered log cabins.

CNC Precision for Perfect Assembly

Every component of the Harrisons’ twin-skin log cabin was cut on our state-of-the-art CNC machinery to tolerances of ±0.1mm. This precision engineering was critical for several reasons:

- First-time assembly success: With only one opportunity to get materials to the site (via boat), there could be no errors or missing components

- Interlocking integrity: The tight-fitting saddle notch joints ensured structural stability without relying on excessive fixings

- Thermal performance: Precise milling maintained the integrity of the insulation cavity throughout the structure

Unlike mass-produced cabins where components are cut to approximate dimensions, our CNC manufacturing guaranteed that every log, every window rebate, and every door aperture would fit together perfectly—even when assembled by a small team in challenging conditions.

Premium Materials for Lakeside Durability

For this lakeside application, material selection was paramount. We specified:

- Slow-grown Scandinavian Spruce: Chosen for its exceptional dimensional stability in humid conditions

- 28mm reinforced glass: Providing safety and thermal performance for large window areas

- Tilt-and-turn glulam windows: Allowing secure ventilation even during brief absences

- Fully insulated door panels: Eliminating the cold bridging common in standard log cabin doors

The Harrisons particularly appreciated our use of joinery-grade glulam (glued laminated timber) for all windows and doors. Unlike solid timber that warps with humidity changes, glulam’s engineered layers counteract natural movement, maintaining perfect alignment through seasonal cycles. This stability was essential for the lakeside environment where humidity levels fluctuate dramatically.

Modular Construction for Waterborne Delivery

The most innovative aspect of this project was our approach to delivery. Recognizing the site constraints, we designed the cabin in modular sections that could be safely transported by boat:

- Pre-assembled wall sections: Two-person manageable sizes that maintained structural integrity

- Waterproof packaging: Each component sealed against lake moisture during transit

- Sequential delivery plan: Components organized in precise assembly order to minimize on-site handling

This modular approach—only possible because of our direct manufacturing control—turned what could have been a logistical nightmare into a smooth operation. The entire cabin was delivered in three boat trips, with assembly beginning immediately upon arrival of the first components.

The Installation: Building Excellence Where Others Couldn’t

The installation phase demonstrated why working with the actual manufacturer—not a reseller—makes all the difference for challenging projects.

Site Preparation: Minimal Impact, Maximum Stability

Rather than the extensive groundwork required for conventional construction, our team implemented a low-impact foundation solution perfectly suited to the lakeside location:

- Ground screw system: Installed with minimal soil disturbance, providing stable support without concrete

- Ventilated subfloor: Allowing air circulation beneath the cabin to prevent moisture buildup

- Precise leveling: Critical for maintaining the integrity of the twin-skin system

This foundation approach not only respected the sensitive lakeside environment but also addressed the unstable soil conditions that would have complicated traditional construction. The entire preparation took just two days—compared to the two weeks typically required for conventional foundations.

Assembly Process: Precision Meets Practicality

With the components safely delivered by boat, our experienced installation team began assembly:

- Wall construction: Starting with the twin-skin perimeter walls, ensuring perfect alignment of the interlocking system

- Roof installation: Incorporating additional insulation layers to match the wall performance

- Window and door fitting: Installing the tilt-and-turn glulam units with precision seals

- Interior finishing: Adding insulation, vapour barriers, and final wall treatments

The entire assembly took just six days—remarkably fast considering the site constraints. This speed was possible because every component had been engineered to fit perfectly, eliminating the “adjustments” and “workarounds” common with less precise construction methods.

Most impressively, the entire process generated minimal disruption to the surrounding environment. There was no heavy machinery, no extensive site clearing, and no prolonged construction noise—just the quiet efficiency of skilled craftspeople working with perfectly engineered components.

The Finished Space: A Year-Round Entertainment Hub

The completed Country Range Twin-Skin Log Cabin transformed the Harrisons’ lakeside property in ways they hadn’t imagined possible.

Thermal Performance: Comfort in All Seasons

The most immediate impact was the cabin’s year-round usability. During our follow-up visit six months after installation, the temperature inside registered a comfortable 21°C despite outside temperatures of just 5°C. The family reported using the space regularly throughout the winter months—a feat impossible with standard single-skin cabins.

The secret? Our twin-skin system’s integrated insulation cavity, which eliminates thermal bridging and prevents condensation. No more damp surfaces, no more mold concerns, just consistent comfort with minimal heating requirements. A single 1.5kW panel heater proved sufficient even during the coldest Lake District days.

Multi-Functional Design: Gaming, Relaxing, and Overnight Stays

The cabin has become the family’s favorite gathering spot for multiple activities:

- Game nights: The pool table area with optimized lighting has hosted countless friendly competitions

- Board game corner: A dedicated space with comfortable seating for quieter strategy games

- Occasional overnight stays: The flexible partition system converts part of the space into a cozy sleeping area

- Summer relaxation: The tilt-and-turn windows create perfect cross-ventilation on warm days

What’s remarkable is how seamlessly the space transitions between these different functions. The high-quality joinery and precise construction mean doors and windows operate smoothly even after a full year of use—a testament to the stability of our Scandinavian spruce and glulam components.

Environmental Harmony: Blending with the Lakeside Setting

Perhaps the most satisfying aspect for the Harrisons was how naturally the cabin integrated with their lakeside environment. The natural wood finish has weathered beautifully, complementing rather than competing with the surrounding landscape. The large windows frame picturesque views of the lake while maintaining excellent thermal performance.

The cabin has become a destination in itself—a place where family and friends gather not just for the games, but for the experience of being surrounded by nature while enjoying modern comfort.

Why Twin-Skin Log Cabins Are Revolutionizing Outdoor Living Spaces

The Harrisons’ lakeside game room is just one example of how twin-skin insulated log cabins are transforming what’s possible in outdoor living spaces. From Brighton to the Scottish Highlands, homeowners are discovering that these engineered structures offer solutions where conventional building methods fall short.

Game Rooms and Clubhouses: The Perfect Application

Game rooms and clubhouses represent an ideal use case for twin-skin log cabins because they demand:

- Year-round usability: Unlike seasonal garden sheds, gaming spaces should be enjoyable in all weather

- Acoustic performance: The insulated cavity naturally dampens sound transmission

- Flexible layouts: Our modular designs accommodate everything from pool tables to card tables

- Customization: Personal touches that make the space uniquely yours

Whether you’re creating a dedicated games room, a private clubhouse, or a multi-functional entertainment space, the twin-skin system delivers the performance and flexibility needed for genuine year-round enjoyment.

The Country Range Difference: Rustic Charm Meets Modern Performance

Our Country Range stands apart from conventional log cabins through its perfect balance of traditional aesthetics and contemporary engineering. While maintaining the rustic appeal that makes log cabins so desirable, each Country Range cabin features:

- Authentic interlocking design: Pioneered by our engineering team for maximum structural integrity

- Premium Scandinavian Spruce: For exceptional stability in British weather conditions

- 28mm reinforced glass: Safety and thermal performance in one package

- Tilt-and-turn glulam windows: The gold standard in cabin glazing

- Fully insulated door panels: Eliminating cold bridging at the most vulnerable points

This combination creates a building that looks like it belongs in the countryside while performing like a modern, energy-efficient structure. The Country Range offers the best of both worlds—traditional charm with contemporary comfort.

The Factorycabins.com Difference: Quality You Can Trust

What sets our twin-skin log cabins apart isn’t just the engineering—it’s our commitment to quality at every stage:

- Direct manufacturing: No middlemen means no compromise on materials or craftsmanship

- Authentic interlocking design: Pioneered by our Lithuanian engineering team

- Scandinavian spruce: For superior stability in British weather conditions

- 28mm reinforced glass: Safety and thermal performance in one

- Tilt-and-turn glulam windows: The gold standard in cabin glazing

When you choose a Factorycabins.com twin-skin log cabin from our Country Range, you’re not just buying a building—you’re investing in a space that will enhance your lifestyle for decades to come.

Create Your Own Lakeside Retreat

The Harrisons’ story demonstrates what’s possible when innovative engineering meets thoughtful design. Their lakeside game room isn’t just a cabin—it’s become the heart of their family’s outdoor living experience.

Whether you’re dreaming of a compact games room for weekend card nights or an expansive clubhouse for larger gatherings, our Country Range offers the perfect solution. With options ranging from 20m² to 50m², and complete customization available, we can create the ideal space for your specific needs.

Most importantly, our twin-skin technology ensures that your new space will be usable 365 days a year—not just when the weather cooperates. This isn’t a seasonal novelty; it’s a genuine extension of your living space.

If you’ve been considering adding a game room, clubhouse, or multi-functional outdoor space to your property, now is the time to explore what’s possible with modern twin-skin log cabin technology. Contact our design team today for a consultation, and let us help you create the outdoor space you’ve always wanted—one that works as hard as you do, in every season.

Log cabins for sale shouldn’t mean compromising on quality or performance. With Factorycabins.com, you get the perfect blend of traditional craftsmanship and modern engineering—delivered directly from the manufacturer to your property, wherever you are in the UK. Visit our Country Range at https://factorycabins.com/product-category/country-range/ to discover the full range of possibilities for your garden.

Please send us an email to sales@factorycabins.com

or call 0208 226 5164