Beyond Compromise: Why Your Next Insulated Log Cabin Should Come Direct from the Source FactoryCabins.com

For two plus decades, the British garden building market has maintained on the quiet, pure deception.

Behind the glossy brochures and “factory-direct” claims lies an uncomfortable truth: 98% of most log cabins sold across Sussex and Kent aren’t manufactured locally at all.

They’re mass-produced in anonymous Baltic factories, shipped by trucks, and rebranded, by UK, Irish middlemen who add 40–60% markups without adding a single thought, not all images and photos you see on the web truly represent exactly what you think you are purchasing, please just check out our blog.

Worse still, many of these suppliers are offering designs they never created and can never truly stand behind their integrity or longevity, as purchasing a log cabin, in whatever shape or size from a mass cabin manufacture producer, that offer always low-quality, mass-produced rubbish, that will 99.9% have missing parts, awful windows and doors, and manufactured using quick grown pine! FACT!

“We pioneered the interlocking log cabin designs that define the industry—and we continue to innovate with cutting-edge twin-skin solutions you can truly trust. Quality and integrity always come first.

There is a different path. One that honours craftsmanship, respects the customer’s intelligence, and delivers genuine value by cutting out the rebranding layers entirely.

This path leads not to a UK warehouse, but to Lithuania—where Factorycabins.com has been engineering precision interlocking log structures since before the term “log cabin” became a garden centre cliché.

From Brighton to Margate, to discerning homeowners are discovering that the finest insulated cabins for sale in Sussex and Kent don’t come from British soil—they come directly from the European source that invented many of the designs now copied across the internet. Like the clock house, and twin skin system, and so much more.

This isn’t about geography. It’s about integrity. When you buy direct from the original designers and manufacturers—not resellers—you receive more than a building. You receive accountability, authenticity, and engineering honed over years of genuine innovation and not forgetting, lower pricing.

The Design Legacy: How Lithuania Shaped the Modern Log Cabin Market

Before “log cabin” became synonymous with flimsy garden sheds, a quiet revolution was unfolding in the Baltic states.

While UK suppliers focused on importing basic timber kits, English -Lithuanian engineers—including our team at Factorycabins.com which is a group of English Guys—were pioneering the interlocking corner systems, precision-milled profiles, and structural innovations that now define quality log construction worldwide.

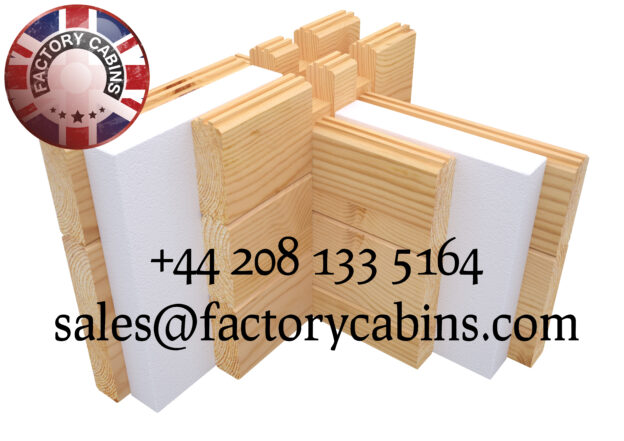

We were among the first European manufacturers to perfect the true interlocking log system—where each timber profile locks mechanically with its neighbour without relying on nails or brackets for structural integrity.

This wasn’t a minor refinement; it was a fundamental reimagining of how timber buildings withstand wind load, thermal movement, and decades of British weather. The tight-fitting saddle notch, the double-tongue wall profile, the self-aligning window rebates—all these features now commonplace online originated in workshops like ours, where engineers understood that a log cabin’s longevity depends entirely on joinery precision.

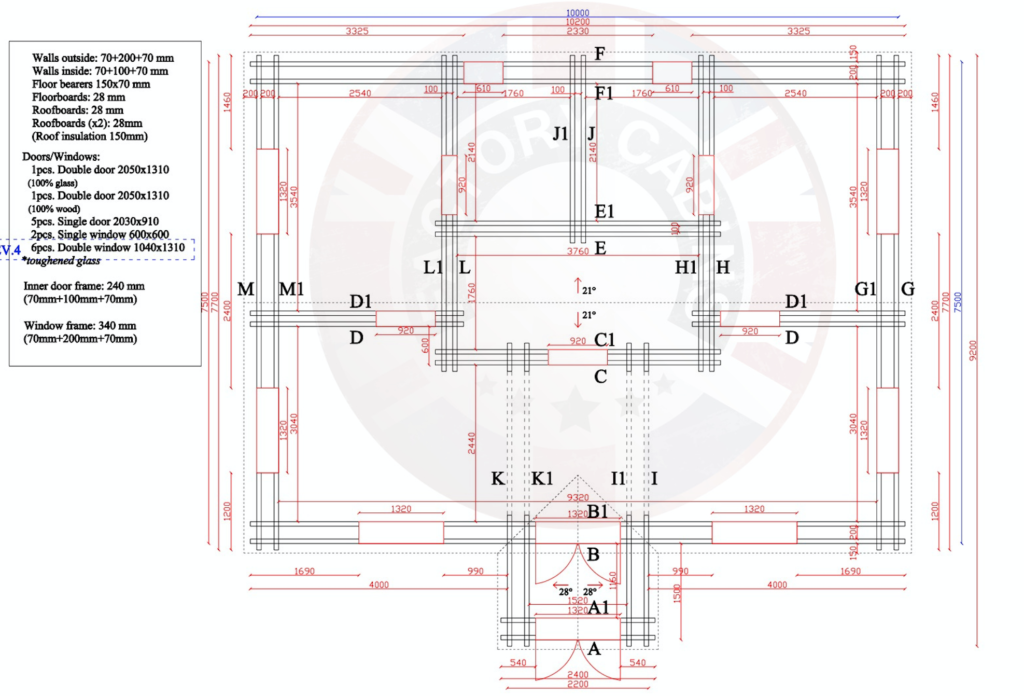

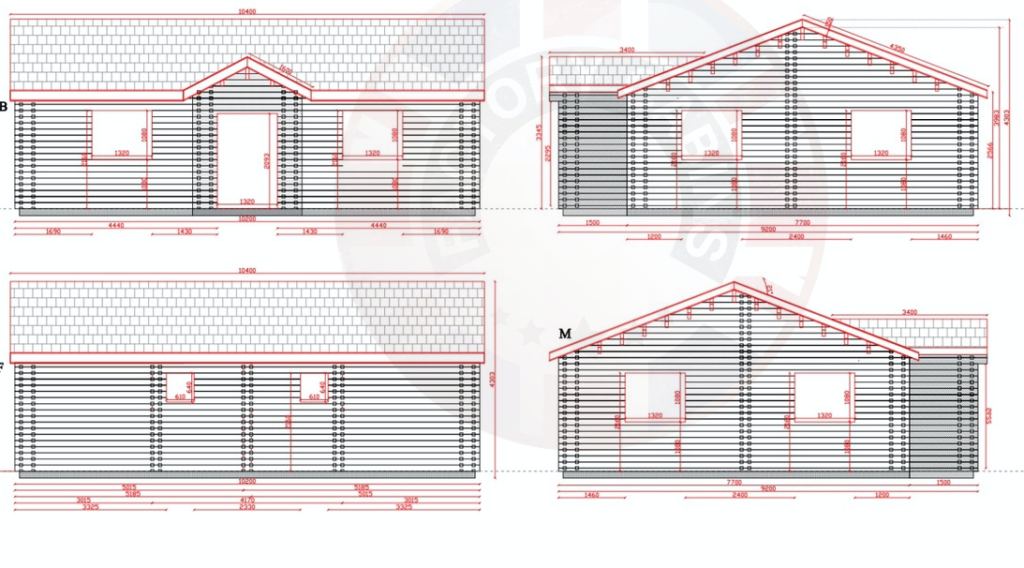

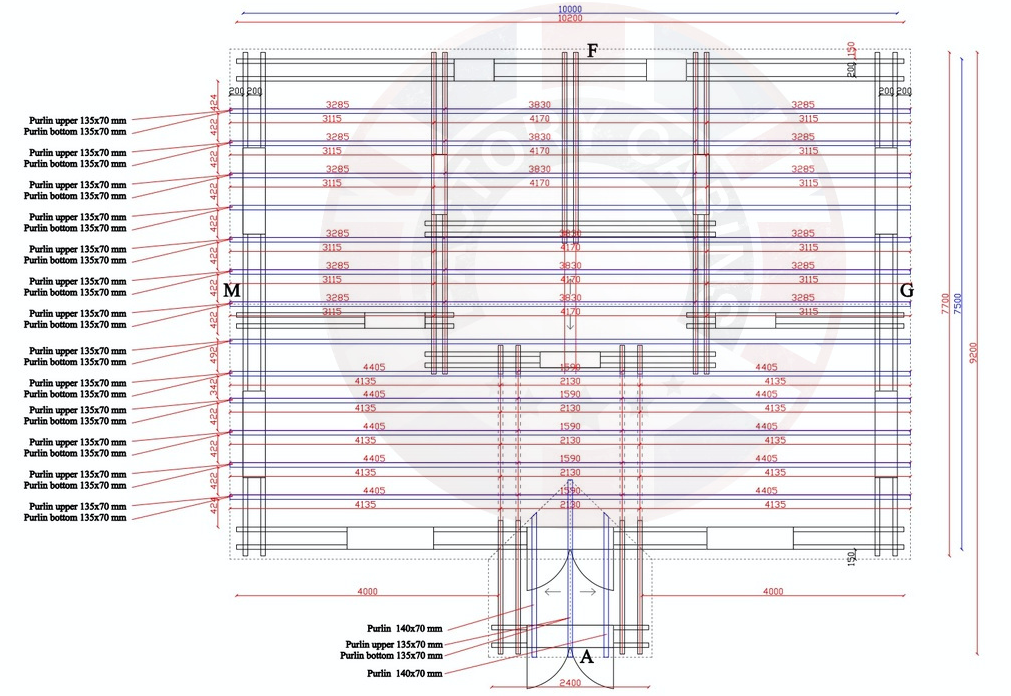

Today, scroll through any UK garden building log cabin websites and you’ll see strikingly similar designs: cabins with porches, the panoramic window studio, the L-shaped corner configuration with integrated veranda. clock house log Cabins, twin skin log cabins, and to manufacture a Twin Skin properly so that it moves as one, and shrinks as one, our first attempt at manufacturing a twin skin was very much like trial and error, and testing went on for about 4 months, till we understood, how joining two separate logs with notching could work, and last the test of time, this is where using the latest CNC machines, and common sense worked well together.

We don’t claim every design—but we do claim authenticity. When you order from Factorycabins.com, you’re not buying a copy. You’re acquiring the original engineering, manufactured by its creators, delivered without the markup of three distribution layers.

This matters profoundly for performance. A copied design loses nuance in translation. Wall thicknesses get reduced. Corner tolerances get widened for “easier assembly.” Insulation cavities get omitted to cut shipping weight. The original engineering intent erodes. But when you buy from the source—from the team that solved these challenges years ago—you receive the complete vision: every millimetre calibrated, every joint engineered for longevity.

Twin-Skin Technology: Perfected for British Climates

What transforms a seasonal novelty into a year-round living space? Insulation—but not the superficial kind added as an afterthought to single-skin walls. True thermal performance demands integrated engineering. This is where our Lithuanian manufacturing advantage becomes undeniable.

Since the ban on Northern Russian timber has come into effect our seasoned Spruce now comes from the Northern most Finnish-Swedish forests, Sweden, and Finland experiences continental winters far harsher than Britain’s maritime climate.

Our engineers design for -25°C—not for occasional frost. This rigorous standard creates twin skin log cabins that perform effortlessly across Sussex and Kent’s milder seasons while remaining comfortable during unexpected cold snaps.

Our twin-skin log cabin system 44mm + 44mm or 70mm + 70mm walls with a precision cavity filled with high-grade insulation delivers U-values as low as 0.18 W/m²K. To contextualise: standard UK building regulations for new homes require 0.30 W/m²K. Our garden cabins exceed residential standards because they were engineered for Lithuanian-Russian-Swiss-Finish-Swedish-Norwegian winters.

The physics is uncompromising.

Single-skin cabins—even at 70mm thickness—cannot match this performance. Timber alone provides limited insulation; beyond 44mm, additional thickness yields diminishing thermal returns while increasing weight, cost, and settlement risk.

Our twin-skin approach solves this elegantly: two structural skins separated by a dedicated insulation zone. Heat cannot bridge the cavity. Moisture cannot penetrate the vapour barrier which is attached to most quality insulation slabs.

The result is a building that stays warm in January and cool in July—with minimal energy input.

For homeowners in coastal Kent or the clay soils of the Weald, this isn’t luxury—it’s necessity. Condensation destroys timber from within. Mould compromises air quality.

Seasonal usability wastes your garden’s potential. Our cabins eliminate these failures at the design stage because we learned these lessons decades ago. What British suppliers now market as “innovative insulation” has been standard practice in our workshop since the early 2003.

Scandinavian Spruce: Sourced Responsibly, Processed with Precision

Timber quality separates enduring structures from disposable kits. While mass-market suppliers use fast-grown pine with high resin content and unpredictable shrinkage, we specify only slow-grown Scandinavian Spruce—sourced from FSC-certified forests in Sweden and Finland, then precision-milled in our Lithuanian facility.

Why spruce? Density and stability. Spruce’s tight growth rings—formed during harsh Nordic growing seasons—deliver superior dimensional stability compared to pine. When humidity shifts between Sussex’s damp autumns and dry summers, spruce moves minimally.

Pine warps. Spruce endures. This stability is non-negotiable for twin-skin construction, where alignment between inner and outer walls must remain perfect for decades. A warped log compromises the entire insulation system. We refuse that risk.

Our CNC machinery—calibrated daily to ±0.1mm tolerances—transforms this premium timber into precision components. Every notch, every rebate, every window aperture is milled to exacting specifications. This isn’t automated cutting alone; it’s automated craftsmanship. The same engineering team that designed our interlocking systems oversees production, ensuring digital precision serves structural intent. When your cabin arrives in Kent or Sussex, every log fits as intended—no forcing, no gaps, no “settling adjustments” required after assembly.

Glulam Joinery: Windows and Doors Engineered for Coastal Realities

A cabin is only as insulated as its weakest point. For most imported kits, that weakness is the glazing—thin single-pane units with plastic hardware that corrodes within months near Brighton or Margate’s salt-laden air.

Our solution: joinery-grade glulam (glued laminated timber) windows and doors, manufactured to German standards and fitted with toughened double glazing as standard. Glulam’s engineered layers counteract natural timber movement, maintaining perfect alignment through humidity cycles that warp solid timber frames.

Multi-point locking systems use stainless steel components resistant to coastal corrosion. Tilt-and-turn functionality—standard on every aperture—provides secure ventilation during summer storms or when leaving your garden office unattended.

These aren’t “cabin windows.” They’re the same specification used in Scandinavian residential construction. When you close one, you hear a solid seal—not a rattle. You feel smooth operation through seasons of use.

Most importantly, you experience genuine thermal continuity: the window’s U-value matches the wall’s performance, eliminating cold bridging at the most vulnerable junction. In an insulated cabin, this integration isn’t optional—it’s essential.

Direct From Source: Eliminating the UK Middleman Markup

Let’s address the geography question honestly: we manufacture in Lithuania. We do not operate a UK factory. And this transparency is your advantage.

UK-based “manufacturers” often function as importers—they buy container loads of generic cabins from Baltic factories (was a time 80% was ours), add their branding, and sell at inflated prices.

You pay for their showroom in Tunbridge Wells, their sales team’s commissions, their warehousing in Maidstone. None of this improves your cabin’s quality. It only increases your cost.

By ordering direct from Factorycabins.com:

- You eliminate the importer’s margin: No UK company buying containers and rebranding

- You eliminate the distributor’s markup: No regional warehouses adding handling fees

- You eliminate the retailer’s overhead: No garden centre taking 50% to display a model

Instead, your investment flows directly into materials and craftsmanship. We handle logistics ourselves—shipping your bespoke cabin from our Lithuanian workshop to your property in Sussex or Kent with professional transport partners. Assembly can be arranged through vetted local teams who follow our precise protocols, or we provide comprehensive guidance for competent DIY installation.

This model delivers two benefits simultaneously: premium European engineering at prices that undercut UK-branded competitors. You receive the original design—not a degraded copy—without paying for British overheads that add cost without value. When suppliers claim “British-made,” ask whether they manufacture or merely import and rebrand. The distinction determines your cabin’s longevity.

Versatility Without Compromise: From Garden Office to Passive Income

What defines a building’s value? Usability across all seasons. Our twin-skin insulated cabins deliver this consistently—whether positioned on a coastal plot near Whitstable or nestled in the High Weald near Tunbridge Wells.

The Professional Garden Office

Hybrid working demands genuine workspace—not a freezing shed you abandon each November. Our cabins maintain comfortable temperatures with minimal heating (typically 1.5kW suffices even in January). Position your desk to capture morning light through glulam tilt-and-turn windows. Run services through insulated cavities during installation. Create a workspace that enhances productivity 365 days a year.

The Holiday Let Investment

Coastal Kent and East Sussex boast Britain’s strongest short-let markets. A high-quality insulated cabin often qualifies as permitted development—providing instant rental inventory without full planning permission. Our clients in Rye, Hastings, and Folkestone report earning £800–£1,500 monthly from cabins let year-round (not just summer peaks) thanks to genuine thermal performance. This is passive income resilience—impossible with single-skin seasonal structures.

The Multi-Generational Space

Families evolve. Teenagers seek independence. Elderly parents require ground-floor accommodation. Our bespoke service creates cabins tailored to human needs: internal partitions with proper insulation, wet rooms with underfloor heating provisions, kitchenette integrations. These aren’t sheds—they’re functional living spaces enhancing family dynamics without costly home extensions.

Why Sussex and Kent Homeowners Choose Lithuanian Engineering

The Southeast presents unique demands: coastal corrosion near Margate, clay soil movement in the Weald, conservation area restrictions in historic towns. Success requires buildings engineered for resilience—not cosmetic appeal alone.

Lithuanian manufacturing delivers this resilience inherently:

- Coastal durability: Stainless hardware and stable spruce withstand salt air better than pine alternatives

- Structural integrity: Interlocking joinery resists ground movement better than nailed constructions

- Thermal performance: Engineered for harsher climates than Britain experiences

- Design authenticity: Original engineering—not degraded copies of our pioneering work

We understand UK planning nuances across 15+ district councils. We advise on permitted development rights specific to Kent and Sussex. We provide technical documentation accepted by local authorities. Geography doesn’t limit service—commitment does. And our commitment is to deliver source-direct quality to every UK customer who values authenticity over branding.

The True Cost of “British-Branded” Cabins: A Maidstone Case Study

Consider two homeowners in Maidstone seeking a 4m x 5m garden office:

Sarah buys a £3,800 “British-designed” cabin from a Tunbridge Wells supplier. Unbeknownst to her, it’s a generic Baltic import rebranded with a UK label. She pays £750 for assembly. By November, gaps appear at corners. Condensation damages her equipment. She spends £1,100 adding interior insulation (reducing usable space). After 24 months, window hardware corrodes; timber shows early rot. Total investment: £5,650 for a deteriorating seasonal structure.

David invests £8,200 direct from Factorycabins.com—Lithuanian-manufactured, twin-skin 44mm-44mm, delivered to his Maidstone property. From day one, the space remains comfortable year-round. No condensation. Hardware operates smoothly through two coastal winters. After three years, the cabin performs identically to day one—his primary workspace 365 days annually. Total investment: £8,200 for genuine utility.

Sarah paid a “British premium” for rebranded mediocrity. David invested in original engineering without middleman markups. His cabin costs less upfront than Sarah’s deteriorating structure will cost long-term—and delivers exponentially greater daily value. This pattern repeats across Sussex and Kent: the cheapest price today becomes the most expensive decision tomorrow.

Your Invitation: Experience Source-Direct Authenticity

We don’t operate showrooms in Brighton or Canterbury. We don’t employ commissioned sales staff. What we offer is more valuable: direct access to the engineers who design and manufacture your cabin. Full bespoke available.

We invite you to:

- Review our design archive—the original interlocking systems copied across the internet

- Request a bespoke quote based on your exact Sussex or Kent property requirements

- Speak directly with our design team in Lithuania (fluent English speakers) to discuss integration with your site

- Examine material samples shipped to your UK address before ordering

No pressure. No fabricated scarcity (“only 3 left!”). Just honest consultation about how authentic Lithuanian engineering can enhance your garden’s utility for decades.

Value Flows from Source to Site—Not from Branding to Buyer

The garden building industry thrives on obfuscation: hiding origins, inflating specifications, rebranding imports as “British.” This model serves suppliers—not customers. It creates a cycle of disappointment where structures fail quickly, forcing replacement rather than delivering decades of service.

We reject this entirely. By manufacturing twin-skin insulated cabins at the source—in Lithuania where interlocking log engineering matured decades ago—we deliver buildings that perform as living spaces, not seasonal novelties.

We can also manufacture a fully timber frame net zero version, which means, savings from day one.

(( A compact net zero cabin timber frame —two bedrooms, bath, living space, kitchen—delivers exceptional ROI. Generate year-round passive income as holiday lets across Sussex and Kent. Minimal energy costs. Often permitted development. Rising demand for sustainable stays. Appreciates while larger properties stagnate. Small footprint, maximum returns: the smartest garden investment you’ll make.))

By selling direct to UK customers without middlemen, we make this quality accessible at honest prices.

This isn’t about nationality. It’s about authenticity. When you order a log cabin for sale in Kent or Sussex, you deserve to know its origins.

You deserve engineering integrity—not rebranded copies. You deserve materials specified for longevity—not for container optimisation. You deserve pricing that reflects manufacturing cost—not layered markups.

From Brighton’s seafront to Margate’s coastline, from the orchards of Kent to the hills of Sussex, your garden deserves better than compromise. It deserves source-direct engineering: twin-skin insulated cabins conceived and crafted by the pioneers of interlocking design, delivered without intermediaries, priced with integrity.

The finest cabins for sale in Sussex and Kent don’t carry British labels. They carry Lithuanian engineering—and the quiet confidence of knowing you’ve bought from the source, not the seller.

Ready to acquire an insulated log cabin engineered at source—not rebranded by resellers? Contact Factorycabins.com today for a bespoke consultation. We manufacture in Lithuania. We deliver across Sussex and Kent. We answer directly to you—the customer—not to middlemen. Let’s build something authentic together.

Please send us an email to sales@factorycabins.com

or call 0208 226 5164