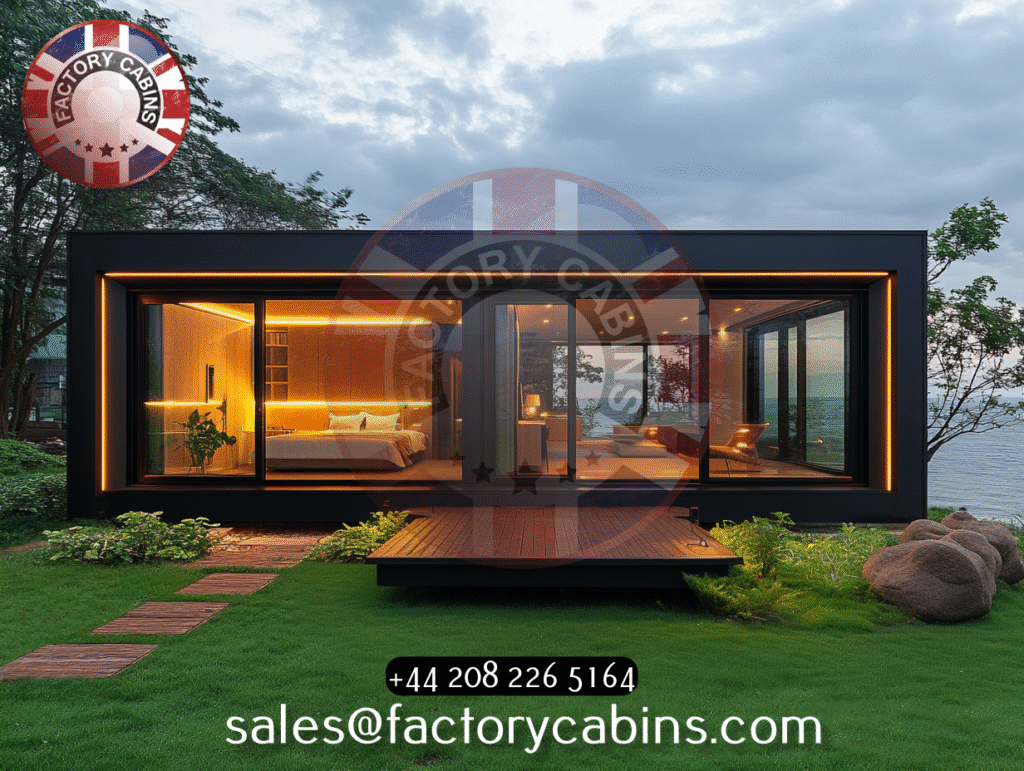

Let’s cut through the noise: a Net Zero home isn’t about politics or climate activism—it’s about your wallet.

Energy bills are soaring and show no sign of falling.

The single most effective way to slash those costs—by 50%, 70%, even more—is to live in a home that barely needs heating or cooling.

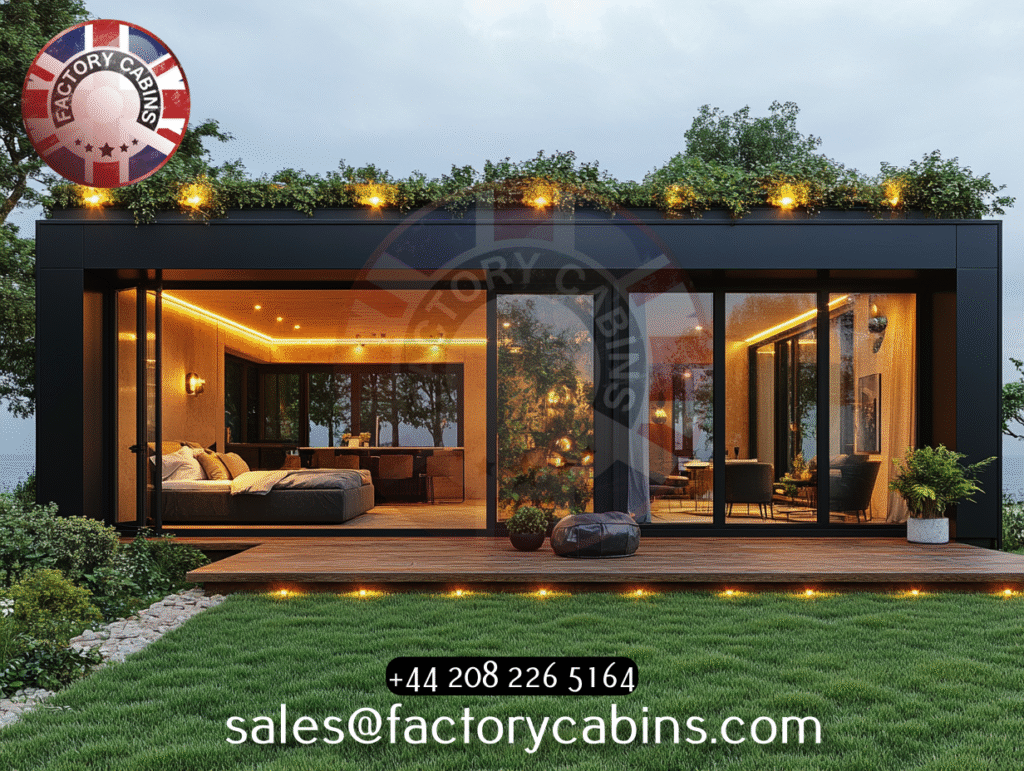

And that’s exactly what a timber frame Net Zero home delivers. Built with precision in a factory, super-insulated (we use Knauf in floors, walls, and roofs), and made airtight from day one, these homes trap heat in winter and stay cool in summer—naturally.

We fit tripple Glazzing as standard in all our windows and doors..

No guesswork, no drafts, no wasted energy.

Forget abstract debates about greenhouse gases for a moment. This is practical: if your house leaks heat, you’re paying to warm the sky. If it’s airtight and insulated like a high-performance timber cabin, you keep that warmth—and your money—right where it belongs: inside.

Building Net Zero isn’t hard or slow. With modern timber frame methods, it’s faster, smarter, and more affordable than ever.

And the best part? You start saving the moment you move in.

So yes—Net Zero is about the planet.

But even if it weren’t, it would still be the smartest financial decision you’ll make for your home.

Because in today’s world, efficiency isn’t optional—it’s essential.

The Future of Timber Frame Construction:

How Factory Cabins Is Redefining High-Performance, Net Zero-Ready Buildings.

In an era defined by climate urgency, energy insecurity, and a growing demand for sustainable living, the construction industry stands at a pivotal crossroads.

Traditional building methods—often slow, wasteful, and energy-inefficient—are being challenged by a new generation of intelligent, factory-built solutions.

At Factory Cabins, we believe the future of construction isn’t just about using wood—it’s about reimagining how timber frame buildings are designed, insulated, and delivered to meet the highest standards of performance, comfort, and planetary responsibility.

Our mission is clear: to build high-quality, highly insulated, Net Zero-aligned timber structures that don’t just meet today’s needs—but anticipate tomorrow’s challenges.

And we do this not through marketing slogans, but through meticulous material selection, precision engineering, and a deep commitment to environmental integrity.

Why Timber Frame? And Why Now?

Timber has been used in construction for millennia—but modern engineered timber takes this ancient material into the 21st century.

Unlike concrete or steel, wood is renewable, stores carbon, and requires far less energy to process. When sourced responsibly, timber is one of the most sustainable building materials on Earth.

But not all timber frame buildings are created equal.

Many so-called “eco-cabins” or “garden offices” on the market today use low-grade timber, minimal insulation, and outdated construction methods that result in poor thermal performance, air leakage, and short lifespans.

At Factory Cabins, we reject this compromise.

We build only with C24-grade structural timber and GL36 glulam beams—engineered wood products known for their strength, dimensional stability, and longevity.

C24 is the European standard for structural softwood, offering superior load-bearing capacity and resistance to warping. GL36 glulam (glued laminated timber) is even stronger used in bridges, stadiums, and high-performance buildings across Europe.

By using these premium materials, we ensure our cabins are not just beautiful and functional but built to last generations.

The Secret Is in the Insulation:

A Whole-Building Approach

A building is only as efficient as its weakest thermal link.

That’s why at Factory Cabins, we take a holistic insulation strategy—treating floors, walls, roofs, and internal partitions as integrated components of a single thermal envelope.

We exclusively use Knauf Insulation—a globally trusted brand renowned for its performance, sustainability, and fire safety.

Specifically, we deploy Knauf’s advanced mineral wool and glass wool products across all building elements:

Floors: High-density Knauf insulation prevents heat loss into the ground—a common issue in poorly insulated cabins.

Our floor build-ups exceed UK Building Regulations, ensuring comfort even in winter.

Walls:

We use Knauf wall insulation with carefully calculated U-values (often below 0.18 W/m²K), far surpassing standard requirements. This minimizes heat transfer and eliminates cold spots.

Roofs:

Roof insulation is critical—up to 25% of heat loss in a building occurs through the roof.

Our cabins feature thick, continuous Knauf roof insulation layers, often combined with airtight membranes and vapour control layers to prevent condensation.

Internal Walls:

Even non-load-bearing partitions are insulated with Knauf acoustic and thermal products, enhancing soundproofing, and maintaining consistent indoor temperatures between rooms.

This comprehensive approach means our buildings achieve exceptional airtightness and ultra-low energy demand—key prerequisites for Net Zero operation. “Insulation isn’t an add-on—it’s the backbone of high-performance architecture.”

Cladding Without Compromise: Beauty Meets Durability While insulation keeps the heat in, cladding protects the building from the elements—and defines its aesthetic character.

At Factory Cabins, we offer a wide range of external and internal cladding options, allowing clients to tailor their building to their environment, taste, and functional needs.

Externally, we work with:

Thermally modified timber (e.g., ThermoWood®): Naturally durable, stable, and chemical-free—ideal for exposed locations.

Western Red Cedar: Beautiful, naturally resistant to decay, and ages gracefully to a silvery grey.

Composite cladding: Low-maintenance, fire-retardant, and available in modern finishes. Also, metal profiles: For a sleek, industrial look with decades of weather resistance.

Internally, choices include:

Plywood and OSB with natural oil finishes for a warm, Scandinavian feel.

Gypsum boards with Knauf acoustic insulation behind for quiet, comfortable interiors.

Reclaimed wood panels for bespoke, character-rich spaces.

Every cladding system is carefully detailed to ensure weather tightness, breathability, and long-term durability—without compromising the building’s thermal performance.

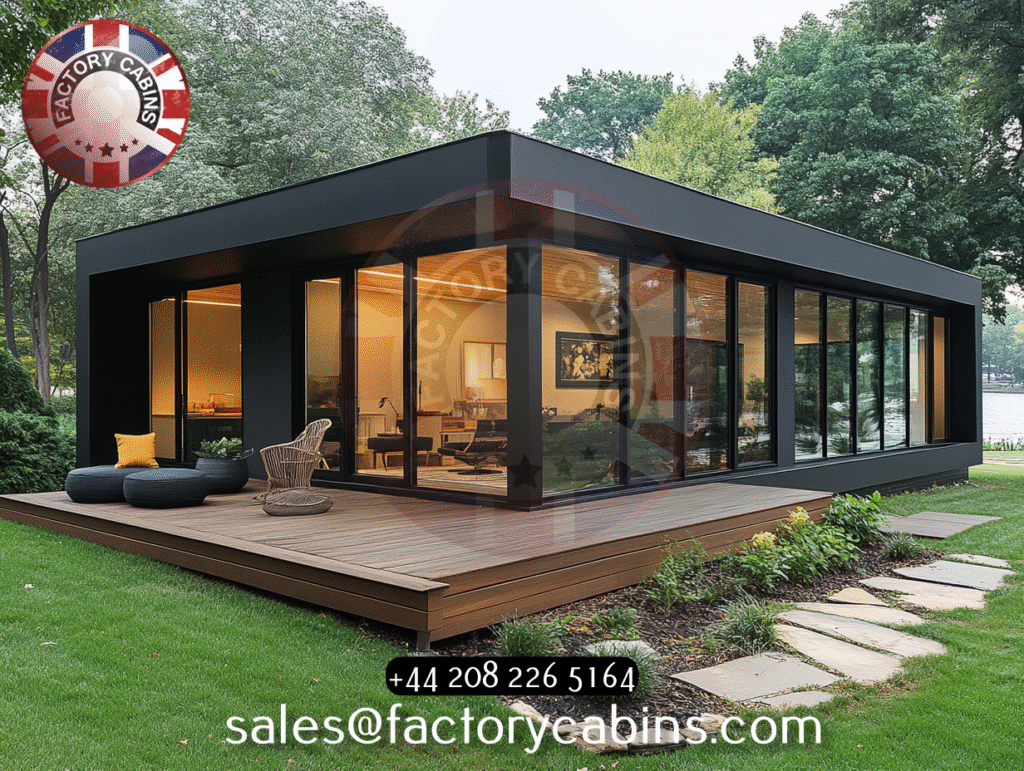

Precision Manufacturing:

Quality You Can Trust

All Factory Cabins are manufactured in a controlled factory environment—not assembled on-site in unpredictable weather.

This allows for: Millimetre-precision cutting and assembly. Consistent quality control Reduced material waste (up to 30% less than traditional builds) Faster on-site installation (often completed in days, not months) Our production process follows strict ISO-certified protocols, and every cabin undergoes rigorous inspection before leaving the factory. From foundation interface to roof apex, every joint, seal, and fastener is engineered for performance. This factory-first approach also means less disruption to your site, lower carbon emissions from construction activity, and higher reliability—because your building is tested before it’s ever exposed to rain or wind.

Built for Net Zero: Aligning with Global Climate Principles

At Factory Cabins, we don’t just talk about sustainability—we embed it into our DNA.

Our buildings are designed to align with the internationally recognised Net Zero framework, as defined by leading climate organisations like the UN-backed Race to Zero campaign and Net ZeroClimate.org. As outlined in their guidelines, a true Net Zero commitment includes:1.

Comprehensive Emissions Coverage (All Three Scopes) We account for: Scope 1:

Direct emissions from our manufacturing facility (minimised through renewable energy use).

Scope 2: Indirect emissions from purchased electricity (offset or sourced renewably).

Scope 3: Emissions from our supply chain—including timber sourcing, transport, and end-of-life. We work only with FSC® or PEFC-certified timber suppliers and prioritise local logistics to reduce transport emissions.

2. Immediate Action + Long-Term Vision

We don’t wait for 2050. Every cabin we build today is Net Zero-ready—designed for ultra-low operational energy use and easy integration with renewable technologies like solar PV, heat pumps, and battery storage.

Many of our clients achieve Net Zero in operation from day one.

3. High-Quality Offsetting (When Needed) While we prioritise emissions reduction at source, we acknowledge that some residual emissions remain. In line with the Oxford Principles for Net Zero Aligned Offsetting, we support carbon removal projects—not just avoidance—and favour long-term, durable storage (e.g., enhanced rock weathering or biochar) over short-term tree planting alone.

4. Equity and Responsibility

We recognise that climate action must be fair. That’s why we advocate for accessible, affordable high-performance buildings—not just luxury eco-homes. Whether it’s a garden office, a classroom, or a family home, everyone deserves a healthy, low-carbon space.5. Transparent Governance

We publish our environmental data, set interim targets, and maintain top-level commitment to continuous improvement—because accountability drives real change. Real-World Performance:

Don’t just take our word for it.

Our cabins-houses-schools-offices-etc consistently outperform expectations:

Winter tests show internal temperatures remain stable with minimal heating—even when outdoor temps drop below freezing. Air leakage tests (where conducted) reveal values well below 3 m³/(h·m²)—the threshold for Net House certification.

Client feedback highlights year-round comfort, low running costs, and exceptional build quality.

One client in the Scottish Highlands reported heating their 30m² cabin for under £150 all winter—thanks to the Knauf-insulated envelope and a small air-source heat pump.

Another, a school in Wales, uses our Net Zero classroom to teach students about sustainability—proving that buildings can be both functional and inspirational.

The Bigger Picture: Timber Frame as a Climate Solution The construction sector accounts for nearly 40% of global CO₂ emissions.

To meet the Paris Agreement goals, we need radical change—and fast. Factory-built, highly insulated timber structures like ours offer a scalable solution: carbon storage:

Each cubic metre of timber stores ~1 tonne of CO. Low embodied energy: Timber requires 20x less energy to produce than steel. Circular potential: At end-of-life, our buildings can be deconstructed, reused, or composted—unlike concrete rubble.

By choosing a Factory Cabin, you’re not just buying a building—you’re investing in a regenerative future. customisation Without Compromise.

Some assume that high performance means rigid design. Not here. Our modular system allows for full customisation—from layout and window placement to roof pitch and interior finishes—while maintaining thermal integrity. Want a vaulted ceiling?

A green roof? Triple-glazed sliding doors?

We engineer it in without sacrificing insulation continuity.

And because we control the entire process—from design to delivery—we ensure that every aesthetic choice aligns with performance goals.

Looking Ahead:

The Road to 2050 Starts Today

The UK’s Net Zero target by 2050 isn’t a distant deadline—it’s a call to action for every builder, homeowner, and policymaker.

Buildings constructed today will still be standing in 2070.

That’s why getting it right now matters more than ever.

At Factory Cabins, we’re proud to lead the shift toward high-performance, low-carbon, human-centred architecture.

We combine the warmth of timber with the precision of modern engineering and the urgency of climate science.

Our buildings aren’t just shelters. They’re statements. Statements that comfort and sustainability go hand in hand.

That beauty doesn’t require waste. That the future of construction is lighter, smarter, and kinder to the planet.

Ready to build your Net Zero future? Explore our range of cabins, or speak to our team about a custom design that meets your needs—and the planet’s.

Factory Cabins: Where timber meets tomorrow.